Abstract

This project describes the development of a reverse vending machine (RVM) that uses AI and computer vision to enhance recycling. YOLOv8 was selected for object detection, trained on 30,000 images of plastic bottles, glass bottles, aluminum cans, and "none of them." The model was optimized with TensorRT and deployed on a Jetson Nano for real-time operation, achieving efficient and accurate waste classification.

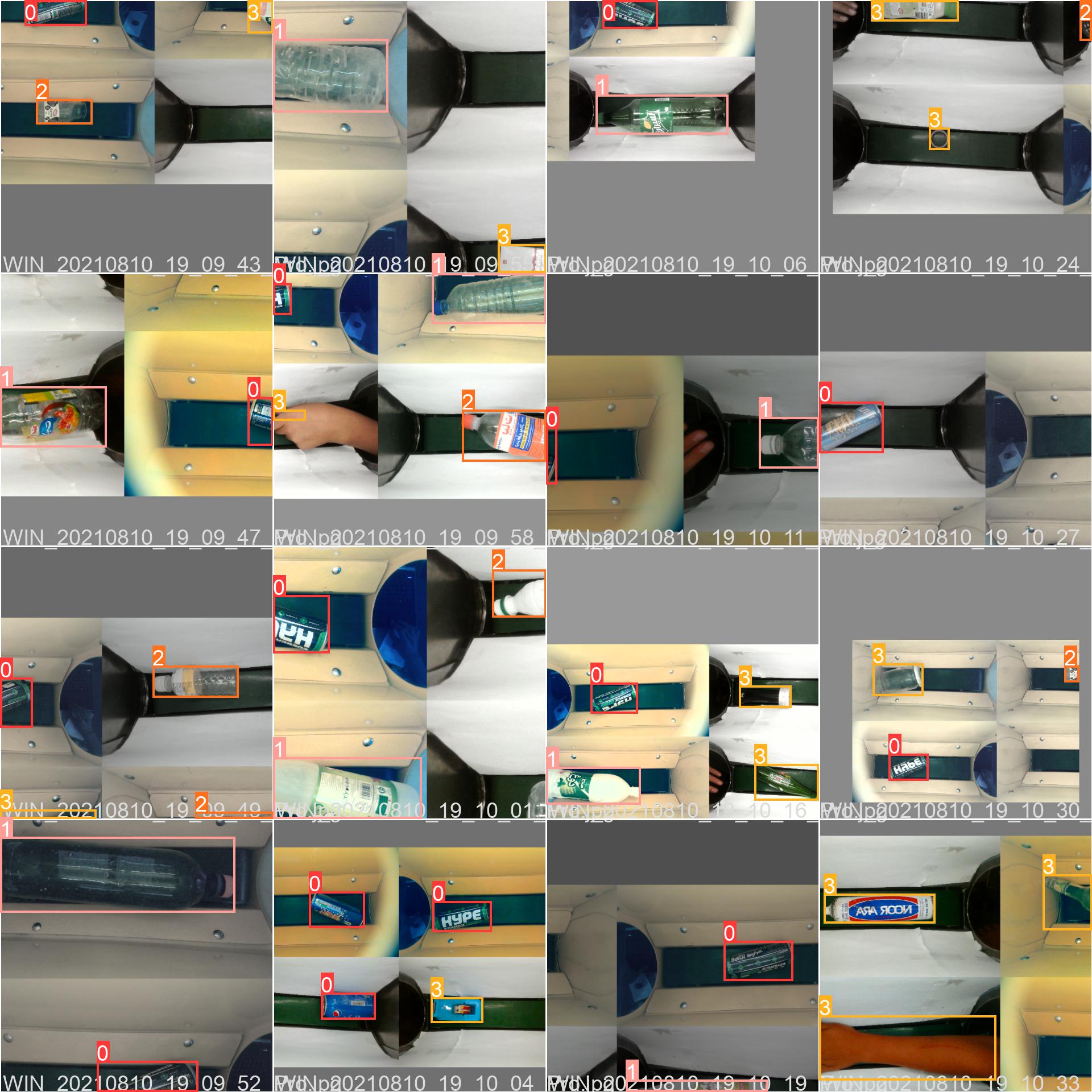

The device Images:

Introduction

Recycling plays a crucial role in promoting environmental sustainability. Reverse vending machines (RVMs) provide a user-friendly way to encourage recycling by automating waste classification. Traditional RVMs rely on predefined shape and weight parameters, which can lead to inaccuracies. This report describes the design and implementation of an advanced RVM system that employs AI and computer vision techniques to accurately classify waste in real-time. The goal is to improve sorting accuracy and efficiency, making recycling more accessible and effective.

Methodology

The methodology comprises five main steps: model selection, data collection and labeling, training, evaluation, and deployment.

-

Model Selection YOLOv8 (You Only Look Once, version 8) was chosen for its state-of-the-art object detection capabilities, high speed, and accuracy. YOLOv8 is particularly suitable for embedded systems due to its lightweight architecture, which ensures efficient performance on devices like the Jetson Nano.

-

Data Collection and Labeling A dataset containing 30,000 images of waste materials was collected. The images represent four classes:

• Plastic bottles

• Glass bottles

• Aluminum cans

• "None of them" (unrelated objects)

Each image was manually labeled using tools like LabelImg to create bounding box annotations. Consistent labeling guidelines were followed to ensure data quality. -

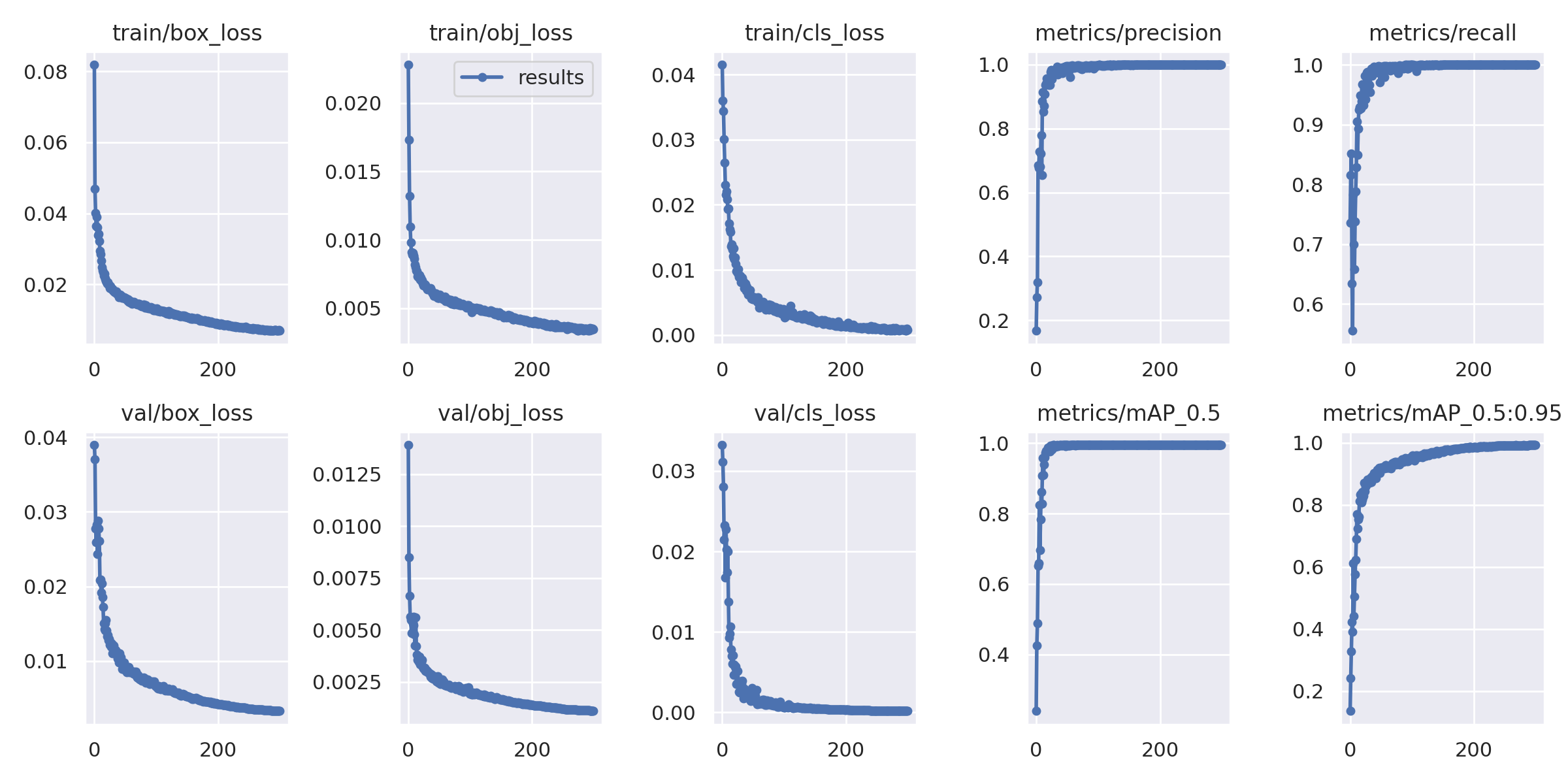

Model Training The labeled dataset was split into training (80%), validation (10%), and testing (10%) subsets. YOLOv8 was trained on this dataset using:

• Initial learning rate: 0.001

• Batch size: 32

• Number of epochs: 500

• Data augmentation: Horizontal flip, random rotation,

The training process was conducted on a high-performance GPU for faster convergence. Loss metrics, such as mean average precision (mAP) and confidence scores, were monitored to ensure optimal model performance. -

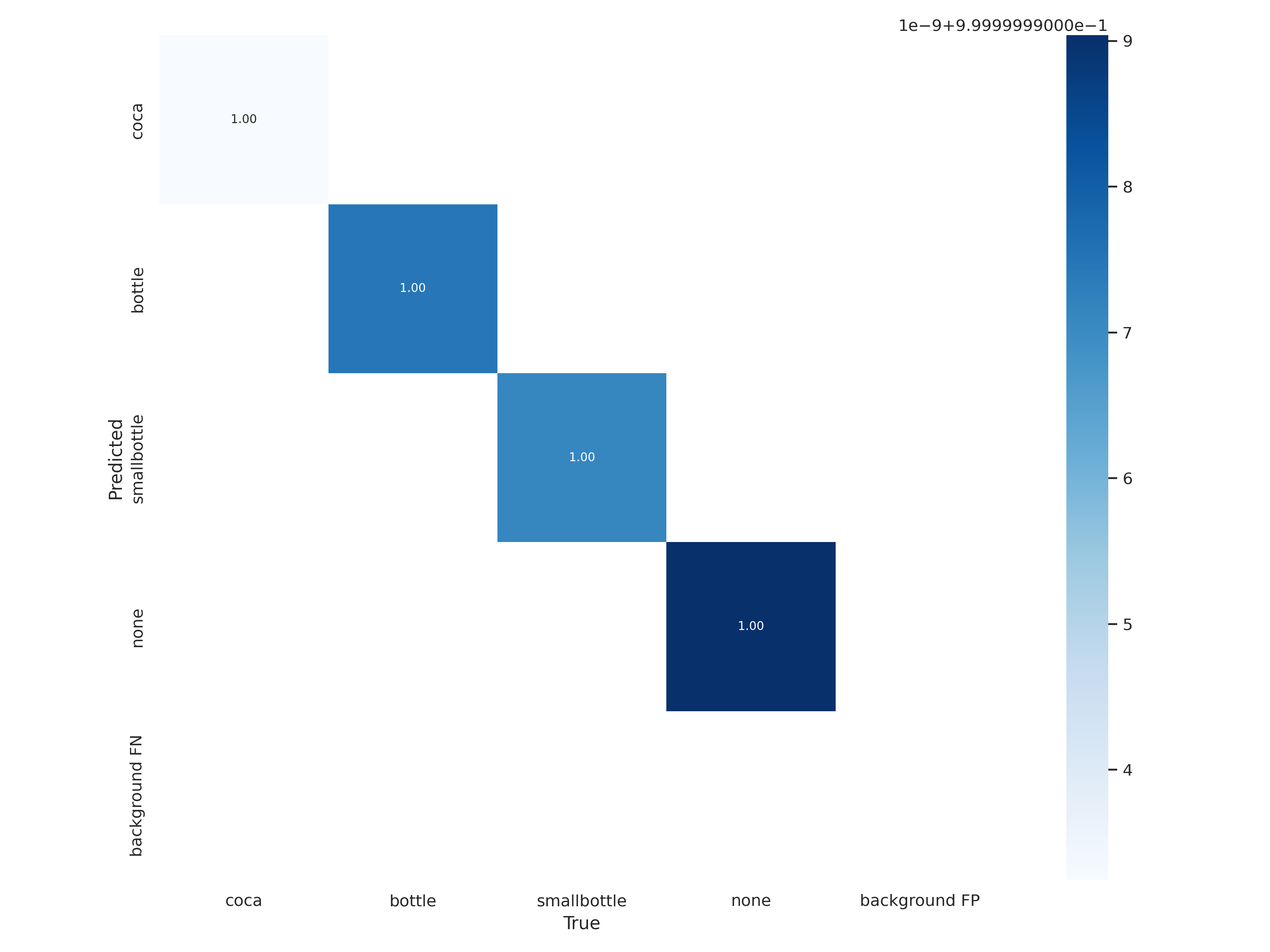

Evaluation The trained model was evaluated on the validation set to measure precision, recall, and overall accuracy. Hyperparameter tuning was performed based on these results. The final model achieved an mAP of 93%, indicating high classification accuracy across all four classes.

-

Deployment To deploy the model on the Jetson Nano, the following steps were taken:

• Conversion of the YOLOv8 model to ONNX format

• Optimization using TensorRT to improve inference speed

• Integration with the RVM’s embedded system for real-time waste classification

The deployment pipeline ensures a frame rate of 25 FPS, meeting the requirements for real-time applications.

Experiments

The deployed system demonstrated excellent performance in real-world scenarios. Key results include:

• Accurate classification of waste materials with a precision of 95% and recall of 92%

• Real-time processing at 12 FPS on the Jetson Nano with TensorRT

• Robust performance under varying lighting conditions and object orientations

The system successfully classified and sorted waste items, minimizing human intervention and error.

Results

Conclusion

The AI-powered RVM efficiently automates waste classification, leveraging YOLOv8 and Jetson Nano for accurate and real-time sorting. Future work will include expanding the dataset, adding more waste categories, and exploring advanced hardware for further enhancements. This solution demonstrates the potential of AI to improve recycling practices and sustainability.

Images are real devices for people's usage and exhibition