Introduction

The shipping industry and modern factories face significant challenges in the maintenance and reliability of their equipment – whether marine engines or industrial machines – which are essential for safe and efficient operations. Unexpected failures can cause operational delays, increased repair costs, environmental risks and direct threats to the safety of operators and crew, as shown by recent studies (Marques & Brito, 2019).

In a vulnerable environment, extreme conditions and the complexity of systems increase component wear, increasing the likelihood of failures if not identified in time (Macnica DHW, 2023). At the same time, in industrial facilities, machines operate under intense conditions – with load variations, expose aggressive environments and high temperatures – which also accelerates the wear of components and compromises the continuity of production.

To mitigate these impacts in both sectors, failure prediction and the implementation of predictive maintenance become essential. This approach allows for scheduled interventions that reduce downtime, optimize operational costs and extend the useful life of equipment (Filtrovali, 2019).

Furthermore, the use of advanced technologies – such as IoT sensors, vibration analysis, thermography and artificial intelligence algorithms – has revolutionized the way data is collected and analyzed. These systems enable continuous monitoring of critical operational parameters, allowing anomalies to be detected at an early stage in both the naval and industrial industries. Thus, it is possible to act before catastrophic failures occur, ensuring safer operation, increasing asset reliability and promoting a significant cost reduction with corrective maintenance.

With the digitalization of the naval industry and the advancement of the Internet of Things (IoT), embedded sensors are widely used to monitor critical operational variables, such as:

- Engine temperature

- Vibration levels

- Lube oil pressure

- Fuel consumption

- Level of mechanical wear

- Occurrence of leaks

Analyzing this data allows you to predict failures before they occur, reducing downtime and optimizing maintenance planning.

Project Summary

Smart Engine AI is an artificial intelligence system that combines autonomous agents, machine learning and physical modeling to transform the monitoring and maintenance of industrial and marine engines. It uses a multi-agent approach to analyze sensor data in real time, predict failures and automate decisions, reducing operational costs and optimizing equipment reliability.Autonomous Agents:

The solution employs a multi-agent architecture, with agents specialized in different tasks:

- Real-Time Engine Data Monitor: Continuously collects, processes, and visualizes engine sensor data, providing real-time insights into engine health and performance.

- Engine Failure Prediction Expert: Utilizes advanced machine learning models to analyze sensor data, detecting patterns that indicate potential failures before they occur.

- Engine Performance Reporting Analyst: Transforms raw engine data into comprehensive reports, highlighting key performance metrics and actionable insights for optimization.

- Engine Maintenance Advisor: Leverages Retrieval-Augmented Generation (RAG) techniques to access and analyze technical manuals, providing highly accurate maintenance recommendations based on real-time diagnostics and historical data.

Technologies Used

- LLMs (Large Language Models): Assist in analyzing and interpreting data to recognize patterns and provide maintenance recommendations.

- Machine Learning Pipeline: Uses trained models to classify the state of motors and predict failures.

- Advanced Sensor Simulation: As this is a theoretical study, we use mathematical functions to simulate combustion engine sensor parameters, ensuring the minimum representation of real operating conditions.

- Report Automation: Agents generate statistical and visual reports on engine operation to support decision making.

Solution Structure

- Data Collection and Processing: Sensors capture variables such as temperature, vibration, pressure, fuel consumption, wear and leaks, feeding the machine learning model.

- Fault Prediction and Intelligent Analysis: Agents use machine learning model predictions about possible engine failures, detect anomalies and suggest corrective actions during operation aiming at performance and safe operation of the equipment.

- Visualization and Decision Making: At the end of the operation, an automated report is generated that presents statistics and trend graphs on the conditions of the engines during the period of operation.

Expected Results

- Cost Reduction: Minimizes emergency maintenance and unexpected failures.

- Greater Reliability and Security: Anticipating problems reduces risks and increases operational security.

- Operational Efficiency: Improves engine performance and fuel consumption.

- Data-Based Strategic Decisions: Facilitates planning and allocation of maintenance resources.

========== Visualization ==========

import matplotlib.pyplot as plt

import seaborn as sns

========== Statistical ==========

from scipy.stats import mannwhitneyu, chi2_contingency

import scipy.stats as stats

========== Machine Learning ==========

from sklearn.ensemble import RandomForestClassifier

from sklearn.linear_model import LogisticRegression

from xgboost import XGBClassifier

========== Data Preprocessing ==========

from sklearn.pipeline import Pipeline

from sklearn.compose import ColumnTransformer

from sklearn.preprocessing import StandardScaler, LabelEncoder

from sklearn.impute import SimpleImputer

========== Data and Assessment Division ==========

from sklearn.model_selection import train_test_split, cross_val_score

from sklearn.metrics import classification_report, confusion_matrix

========== File and Template Management ==========

import joblib

import os

========== Automation and AI==========

from crewai import Agent, Task, Crew

import openai

from langchain_openai import ChatOpenAI

from crewai_tools import DOCXSearchTool

========== Other Utilities ==========

import datetime

import time

import random

import json

import re

========== Environment Variable Management ==========

from dotenv import load_dotenv

========== Warning Suppression ==========

import warnings

warnings.filterwarnings("ignore", category = DeprecationWarning)

warnings.filterwarnings("ignore", category = UserWarning)

warnings.simplefilter(action='ignore', category = FutureWarning)

<!-- RT_DIVIDER -->

## **1. Exploratory Data Analysis**

```python

data = pd.read_csv(r'C:\Users\z004hn4c\Documents\Pump_Project\marine_engine_data_1.csv')

display(data.head())

| timestamp | engine_id | engine_temp | oil_pressure | fuel_consumption | vibration_level | rpm | engine_load | coolant_temp | exhaust_temp | running_period | fuel_consumption_per_hour | engine_type | fuel_type | manufacturer | failure_mode | severity |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2023-01-01 | ENG_001 | 79.816406 | 7.049409 | 1000.000000 | 4.366612 | 1770.214578 | 42.472407 | 78.323108 | 450.0 | 49.741791 | 100.0 | 4-stroke High-Speed | Diesel | MAN B&W | No Failure | Normal |

| 2023-01-08 | ENG_001 | 98.982068 | 8.000000 | 6308.623817 | 3.732792 | 1677.238238 | 77.042858 | 100.000000 | 450.0 | 94.351515 | 100.0 | 2-stroke Low-Speed | Diesel | Mitsubishi | Overheating | Critical |

| 2023-01-15 | ENG_001 | 83.918153 | 8.000000 | 6444.402260 | 4.061372 | 1487.472085 | 63.919637 | 78.178337 | 450.0 | 120.095804 | 100.0 | 2-stroke Medium-Speed | Diesel | Caterpillar | Fuel Issues | Requires Maintenance |

| 2023-01-22 | ENG_001 | 81.887081 | 7.601603 | 4439.946613 | 3.999554 | 1548.624692 | 55.919509 | 82.896344 | 450.0 | 122.321555 | 100.0 | 2-stroke Medium-Speed | Diesel | MAN B&W | No Failure | Normal |

| 2023-01-29 | ENG_001 | 78.550429 | 6.233033 | 3146.234038 | 4.520559 | 1441.151499 | 29.361118 | 80.791150 | 450.0 | 111.978460 | 100.0 | 4-stroke High-Speed | Diesel | Wärtsilä | Mechanical Wear | Critical |

# Checking the format of the columns: data.info()

- Total Entries: 5200

- Total Columns: 17

- Memory Usage: 690.8+ KB

| # | Column | Dtype | Non-Null Count |

|---|---|---|---|

| 0 | timestamp | object | 5200 |

| 1 | engine_id | object | 5200 |

| 2 | engine_temp | float64 | 5200 |

| 3 | oil_pressure | float64 | 5200 |

| 4 | fuel_consumption | float64 | 5200 |

| 5 | vibration_level | float64 | 5200 |

| 6 | rpm | float64 | 5200 |

| 7 | engine_load | float64 | 5200 |

| 8 | coolant_temp | float64 | 5200 |

| 9 | exhaust_temp | float64 | 5200 |

| 10 | running_period | float64 | 5200 |

| 11 | fuel_consumption_per_hour | float64 | 5200 |

| 12 | engine_type | object | 5200 |

| 13 | fuel_type | object | 5200 |

| 14 | manufacturer | object | 5200 |

| 15 | failure_mode | object | 5200 |

| 16 | severity | object | 5200 |

- float64: 10 columns

- object: 7 columns

As you can see we do not have empty columns in the dataset.

1.1 Analysis of Fault Distributions

def plot_bar_with_counts(data: pd.DataFrame, column: str, color: str): """ Plots a bar chart with totals at the top of each bar for the chosen column. Parameters: - data (pd.DataFrame): DataFrame containing the data. - column (str): Name of the categorical column to be plotted. Return: - Displays a bar graph. """ # Count occurrences of each category in the chosen column value_counts = data[column].value_counts() # Create the bar chart plt.figure(figsize=(24, 10)) bars = plt.bar(value_counts.index, value_counts.values, color=color) # Add the values to the top of each bar for bar in bars: plt.text( bar.get_x() + bar.get_width() / 2, bar.get_height(), str(bar.get_height()), ha="center", va="bottom", fontsize=12, fontweight="bold" ) # Chart Settings plt.xlabel(column) plt.ylabel("Quantidade") plt.title(f"Distribuição de {column}") plt.xticks(rotation=45, ha="right") plt.grid(axis="y", linestyle="--", alpha=0.7) # View the chart plt.show()

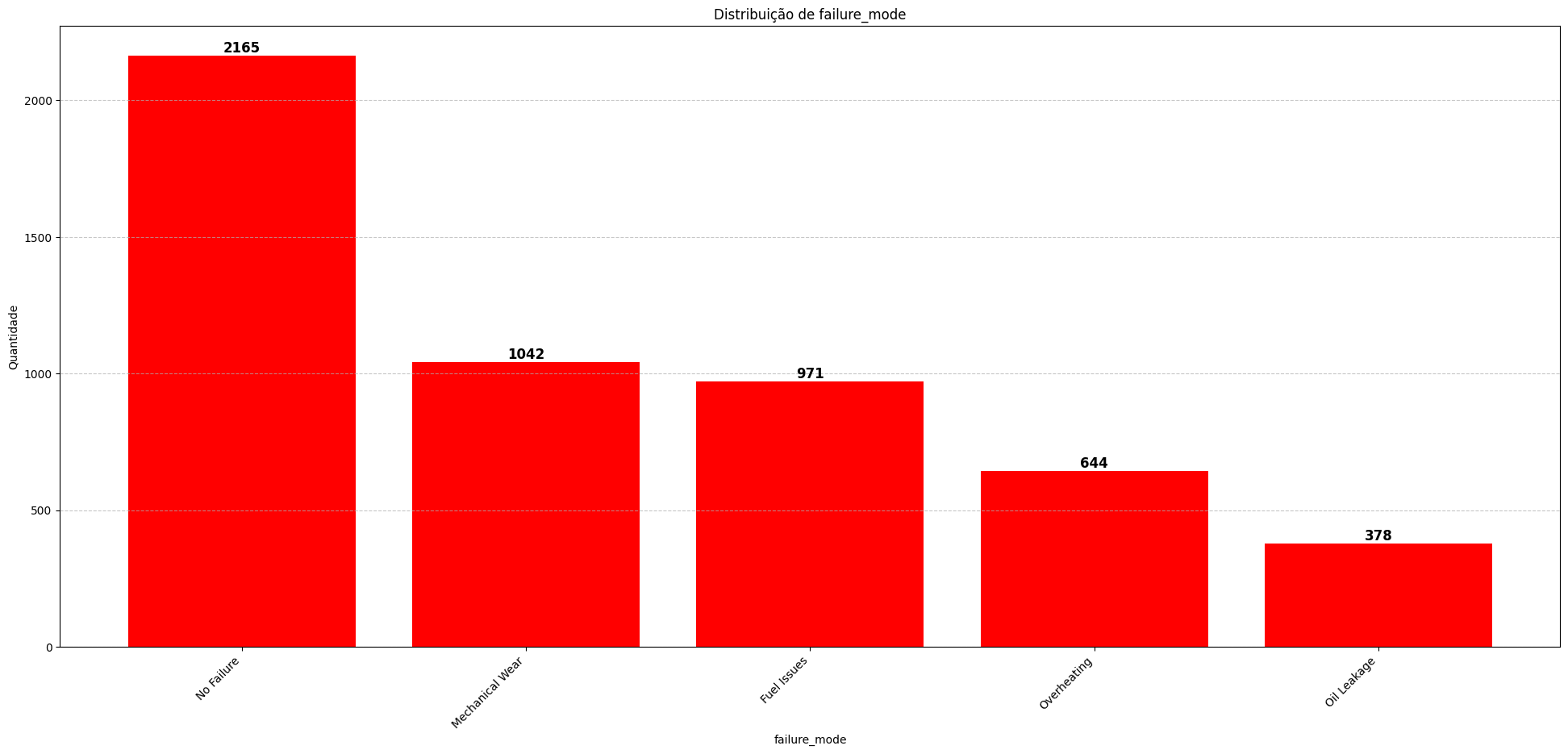

plot_bar_with_counts(data, "failure_mode", color='red')

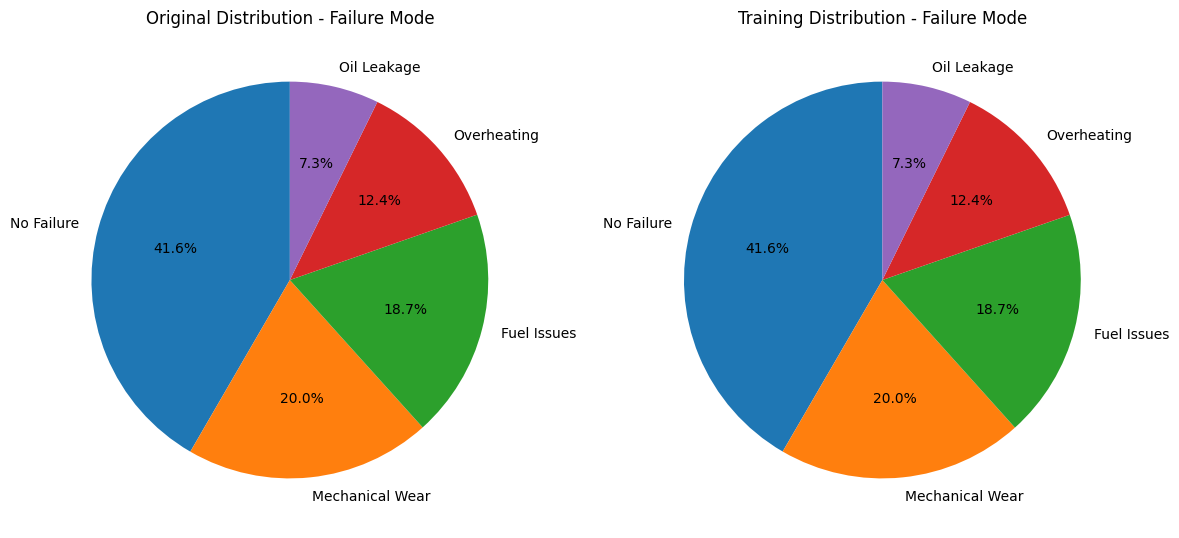

1.1.1 The majority of records (41.6%) correspond to fault-free engines.

- Due to the predominance of the

No Failureclass, a model trained on this dataset may develop a bias to predict this category with high frequency. If this imbalance is not adequately addressed, the model may exhibit high overall accuracy, but poor performance in detecting real faults. - If this imbalance is not adequately addressed, the model may exhibit high overall accuracy, but poor performance in detecting real faults.

Mechanical Wear (20.0%) and Fuel Issues (18.7%) are the most common failures.

- Mechanical wear and fuel-related problems represent more than half of recorded failures, suggesting that these are the main risk factors in engine operation.

- To be useful in predictive maintenance, the model needs to have high accuracy in these categories, ensuring reliable diagnoses.

Oil Leakage and Overheating, represent only 19.7% of cases.

- Although less frequent, these failures can be critical for engine operation.

Overheating, for example, can lead to severe damage and catastrophic failure if not detected in time.

- The model may have difficulty detecting less represented failures, favoring predictions for more frequent classes (

No Failure,Mechanical WearandFuel Issues). - This behavior can compromise the reliability of the monitoring and predictive maintenance system.

- To mitigate this bias, it is essential to apply class balancing techniques, such as Oversampling/Undersampling, assigning class weights and prioritizing metrics such as Recall, ensuring that critical failures are not underestimated.

When exploring the next categorical variables, the distribution of failures will be included to assess whether any category has a higher failure rate or to identify possible patterns. For this, the function

```python

def plot_bar_with_hue(data: pd.DataFrame, column: str, hue: str, palette: str = "Set2"):

"""

Plots a bar chart with totals at the top of each bar, segmented by a hue category.

plot_bar_with_count will be replaced with plot_bar_with_hue:

Parameters:

- data (pd.DataFrame): DataFrame containing the data.

- column (str): Name of the categorical column to be plotted.

- hue (str): Column used for segmentation (e.g., "failure_mode").

- palette (str): Color palette for different categories (default: "Set2").

Returns:

- Displays a bar graph.

"""

plt.figure(figsize=(16, 8))

Create a complete DataFrame with all possible column and hue combinations

all_combinations = pd.MultiIndex.from_product(

[data[column].unique(), data[hue].unique()], names=[column, hue]

)

counts = data.groupby([column, hue]).size().reindex(all_combinations, fill_value=0).reset_index(name="count")

# Create the bar chart

ax = sns.barplot(data=counts, x=column, y="count", hue=hue, palette=palette)

# Add values to the top of each bar (without displaying zeros)

for p in ax.patches:

if p.get_height() > 0: # Only display non-zero values

ax.annotate(

format(p.get_height(), ".0f"),

(p.get_x() + p.get_width() / 2., p.get_height()),

ha="center",

va="bottom",

fontsize=12,

fontweight="bold"

)

Chart settings

plt.xlabel(column)

plt.ylabel("Quantity")

plt.title(f"Distribution of {column} by {hue}")

plt.xticks(rotation=45, ha="right")

plt.grid(axis="y", linestyle="--", alpha=0.7)

plt.legend(title=hue)

# Display the graph

plt.show()

<!-- RT_DIVIDER -->

### **1.2 Analysis of Maintenance Status Distributions**<p>

```python

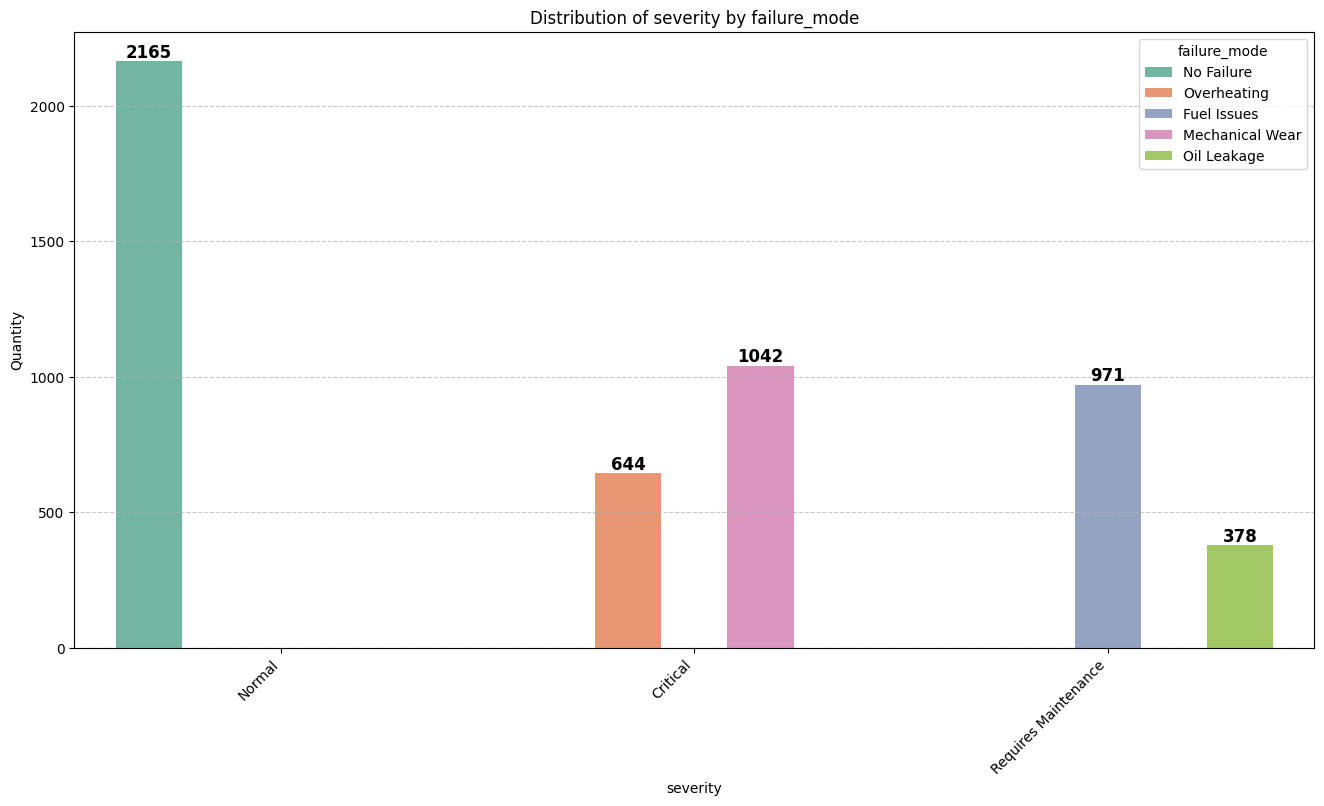

plot_bar_with_hue(data=data, column="severity", hue="failure_mode")

Severity Distribution Analysis

-

Most records are classified as

Normal(41.6%)- The majority of equipment is in normal operating condition, with no recorded failures (2165 occurrences).

- This suggests that most of the time, the equipment functions correctly.

-

Critical failures are primarily caused by mechanical wear (32.4%)

- Mechanical Wear is the leading cause of critical failures, accounting for 1042 occurrences.

- This highlights the importance of preventive maintenance to mitigate wear-related breakdowns.

-

Overheating is the second most common cause of critical failures

- Overheating appears in 644 cases, making it a significant failure mode.

- This suggests that many engines may have cooling system inefficiencies, which require further investigation.

-

The

Requires Maintenancecategory is strongly linked to fuel and oil leak issues (26.0%)- Fuel Issues account for 971 records, indicating a high impact on maintenance needs.

- Oil Leakage is less frequent (378 occurrences) but remains an important factor.

-

Failure patterns based on severity:

- Critical Failures → Mainly associated with mechanical wear and overheating.

- Requires Maintenance → Primarily linked to fuel system problems and oil leaks.

-

Class imbalance consideration:

- The Normal category dominates the dataset, which might lead predictive models to favor this class.

- The Critical and Requires Maintenance categories, while significant, may require rebalancing techniques (e.g., oversampling, weighting) to improve model performance.

-

Preventive maintenance strategies:

- Mechanical Wear and Overheating should be prioritized in critical failure prevention plans.

- Fuel system checks and oil leakage inspections should be reinforced to reduce maintenance needs.

1.3 Analysis of Fuel Type Distributions

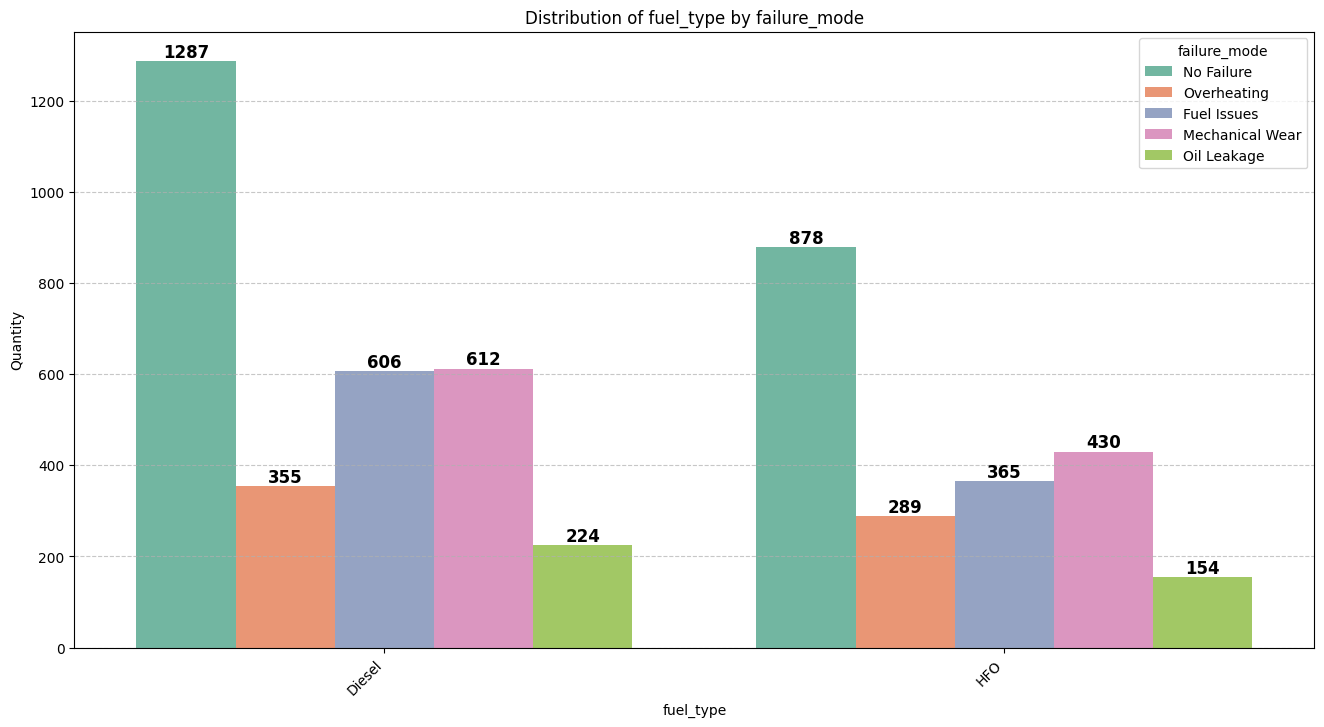

plot_bar_with_hue(data=data, column="fuel_type", hue="failure_mode")

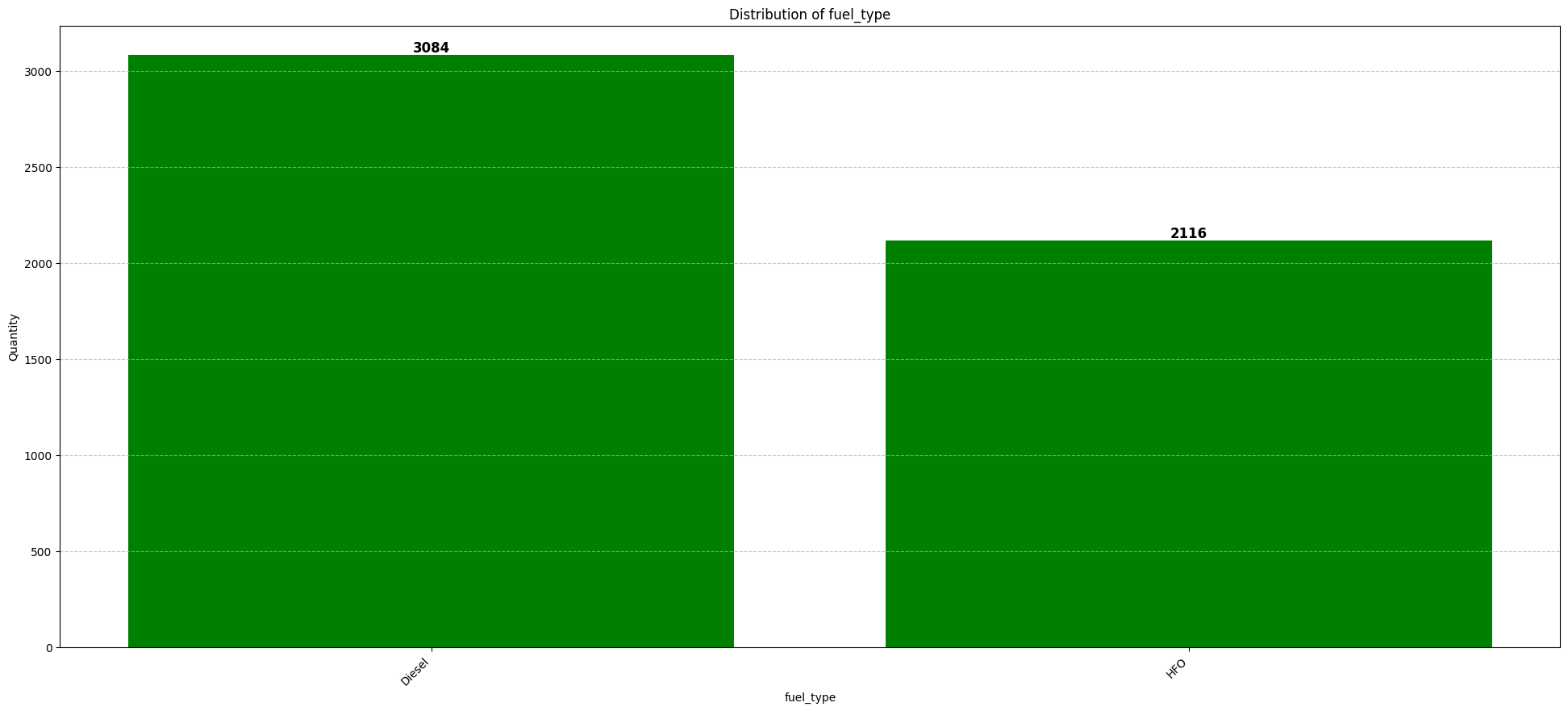

plot_bar_with_counts(data, "fuel_type", color='green')

Fuel Type Distribution Analysis

1.3.1 Higher incidence of diesel failures

- The total number of failures in diesel engines (1797) is greater than that in HFO engines (1238).

- This may indicate that diesel engines are more prone to failures or that there are a greater number of them in the analyzed fleet.

1.3.2 Mechanical Wear as a Major Concern

- Mechanical wear is the most common failure mode in both Diesel (612 cases) and HFO (430 cases) engines.

- This suggests that maintenance efforts should focus on reducing mechanical wear-related issues.

1.3.3 Fewer failures recorded in HFO engines

- The

No Failurecategory has almost the same proportion in HFO engines (41.5%) than in Diesel engines (41.7%). - This may indicate that HFO and Diesel engines have a similar reliability rating and/or a common operating profile.

1.3.4 Specific differences between faults

- Fuel Issues are more common in

Dieselengines (606 vs. 365 inHFO), possibly due to differences in fuel quality or injection systems. Oil LeakageandOverheatingfollow a similar pattern between the two types of fuel, but are still more frequent in Diesel.

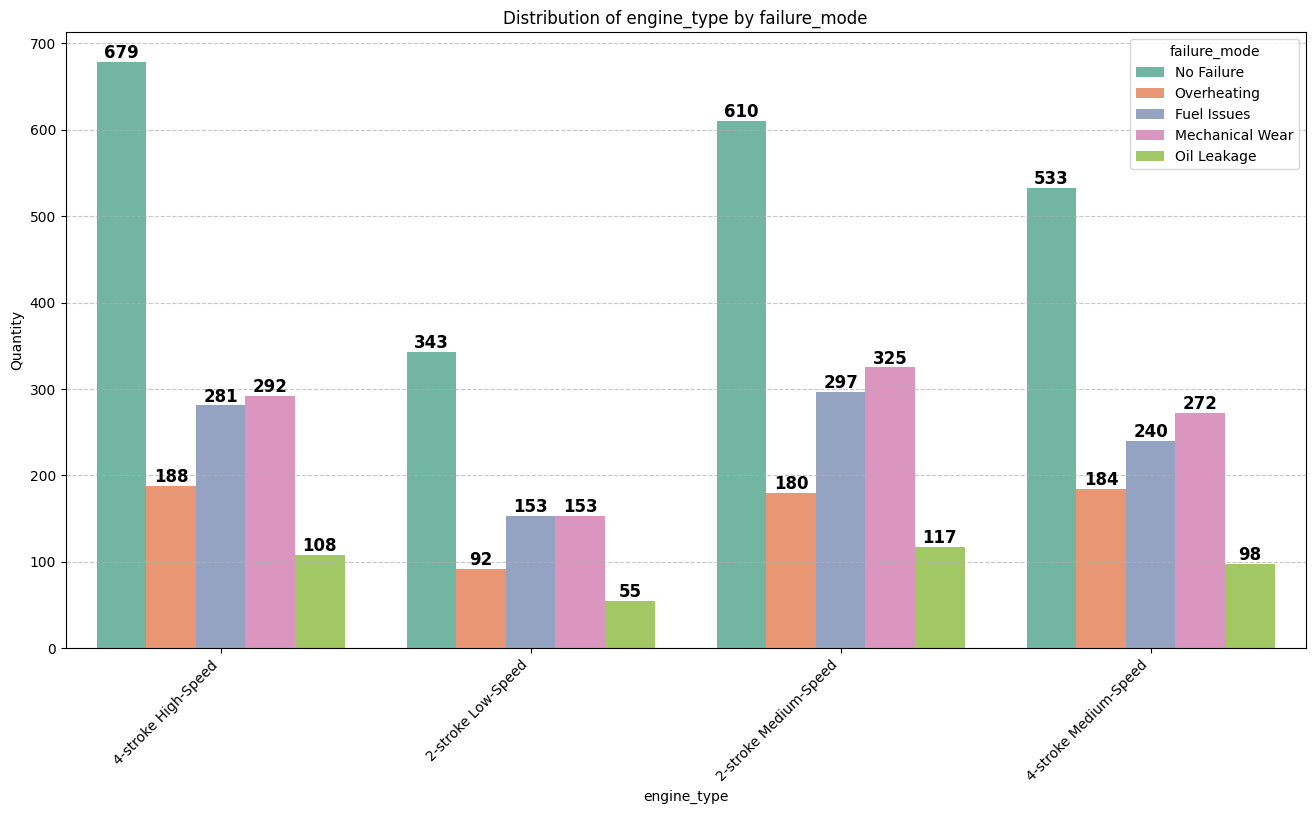

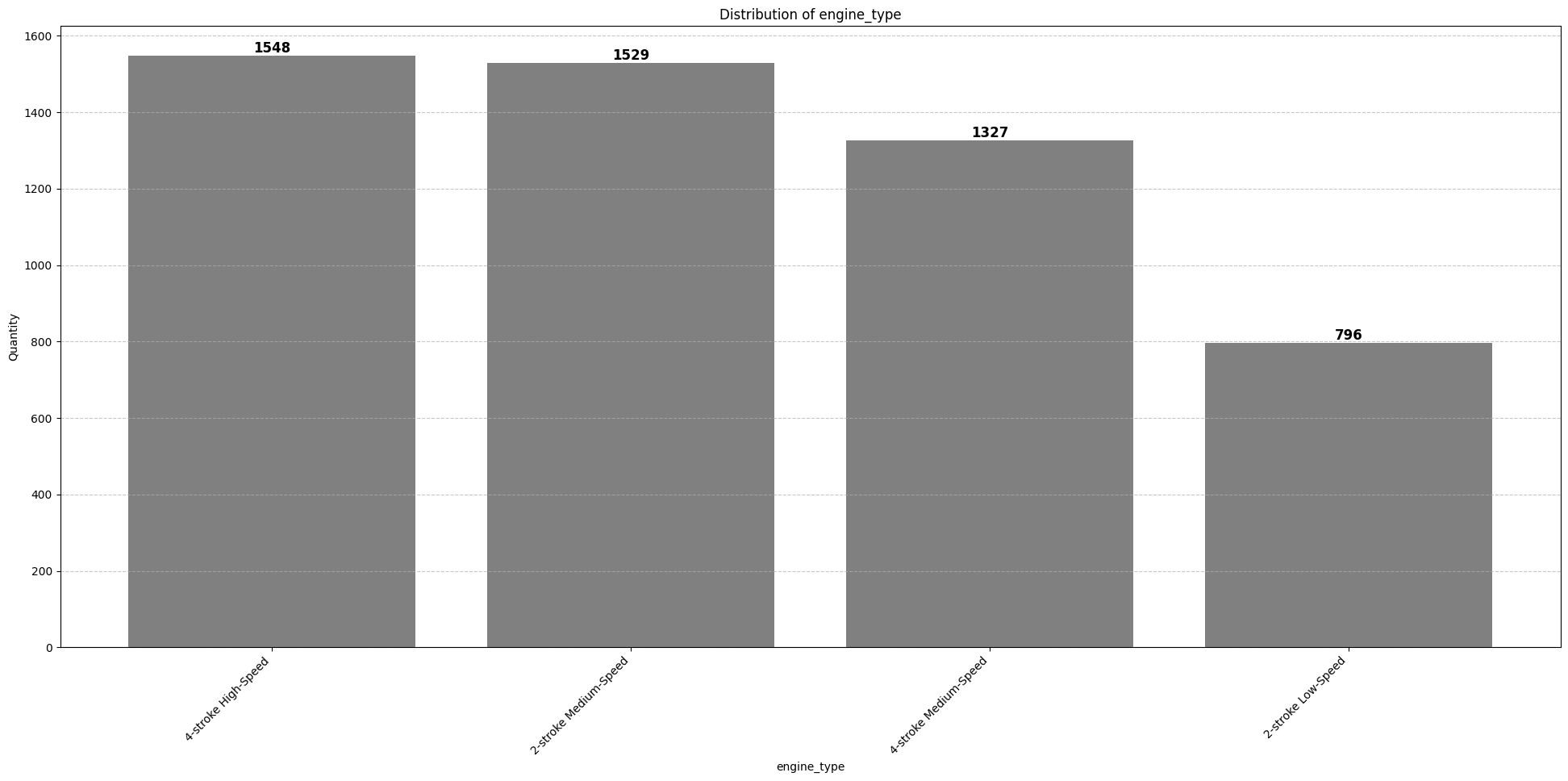

1.4 Analysis of Engine Type Distributions

The distribution of failures by engine type reveals important information about engine behavior and the frequency of failures associated with each type. Below, we can highlight some key points from this analysis:

plot_bar_with_hue(data=data, column="engine_type", hue="failure_mode")

plot_bar_with_counts(data, "engine_type",color='gray')

Engine Type Analysis

1.4.1 Most Engine Types

- 4-stroke High-Speed and 2-stroke Medium-Speed engines are predominant in the dataset, with 1548 and 1529 records, respectively, totaling the majority of the data. This suggests that these types of engines are more common and represent a significant part of the dataset.

- Fault distribution:

- 4-stroke High-Speed and 2-stroke Medium-Speed have the highest amounts of failures associated with various causes, such as No Failure, Mechanical Wear, Fuel Issues, and Overheating.

- The 4-stroke High-Speed engine, for example, has a total of 1548 occurrences, of which:

- 679 are No Failure

- 292 are Mechanical Wear

- 281 are Fuel Issues

- 188 are Overheating

- These engines are more susceptible to mechanical wear failures and fuel issues, which can be expected due to the more intense use of high-performance engines.

1.4.2 Smallest Representation of Low-Speed Motors

- 2-stroke Low-Speed has the lowest number of records, with 796 occurrences in total. This indicates that this type of engine is less common, which may reflect its more specialized and specific application, generally in industrial contexts or in large engines.

- Fault distribution:

- Failures associated with the 2-stroke Low-Speed engine are mainly No Failure (343 records), but also include:

- Mechanical Wear (153 records)

- Fuel Issues (153 records)

- Overheating (92 records)

- The predominance of No Failure in this type of engine may indicate that, despite being less common, low-speed engines are robust and have a lower failure rate.

- Failures associated with the 2-stroke Low-Speed engine are mainly No Failure (343 records), but also include:

1.4.3 Failure Analysis by Engine Type

- Common faults:

- Mechanical Wear is a significant failure for 4-stroke High-Speed and 2-stroke Medium-Speed engines, with 292 and 325 occurrences, respectively.

- This suggests that, even though they are high-performance engines, mechanical wear is still one of the main problems, probably due to the constant use and high operating load of these engines.

- Fuel Issues are also a recurring failure, mainly in:

- 4-stroke High-Speed (281 failures)

- 2-stroke Medium-Speed (297 failures)

- This may reflect fuel-related issues such as contamination or injection system problems, which are more prevalent in high-performance engines.

- Overheating and Oil Leakage are also faults observed in all types of engines, but less frequently, especially in 4-stroke Medium-Speed and 2-stroke Low-Speed engines.

- Mechanical Wear is a significant failure for 4-stroke High-Speed and 2-stroke Medium-Speed engines, with 292 and 325 occurrences, respectively.

1.4.4 Relatively Balanced Distribution

- The distribution of failures by engine type shows a certain balance between categories, but:

- 2-stroke Low-Speed shows fewer Mechanical Wear and Fuel Issues failures compared to other engines.

- This may indicate that low-speed engines are more robust and have a lower failure rate compared to common problems in high-performance engines.

- The 2-stroke Low-Speed category has a lower frequency of associated failures, which can be advantageous, as the analysis model will have to deal with a slight unbalance, except for low-speed engines.

The 4-stroke High-Speed and 2-stroke Medium-Speed engines are the most common in the dataset and, as expected, they present a higher incidence of failures associated with mechanical wear and fuel problems, reflecting the more intensive use of these engines.

In contrast, 2-stroke Low-Speed engines, although they represent a smaller part of the dataset, have a lower failure rate, suggesting that they are more robust and less prone to typical failures, such as mechanical wear or fuel problems.

The distribution of failures by engine type is, in general, balanced, except for 2-stroke Low-Speed engines, which have fewer failures. This distribution facilitates the analysis of engine performance.

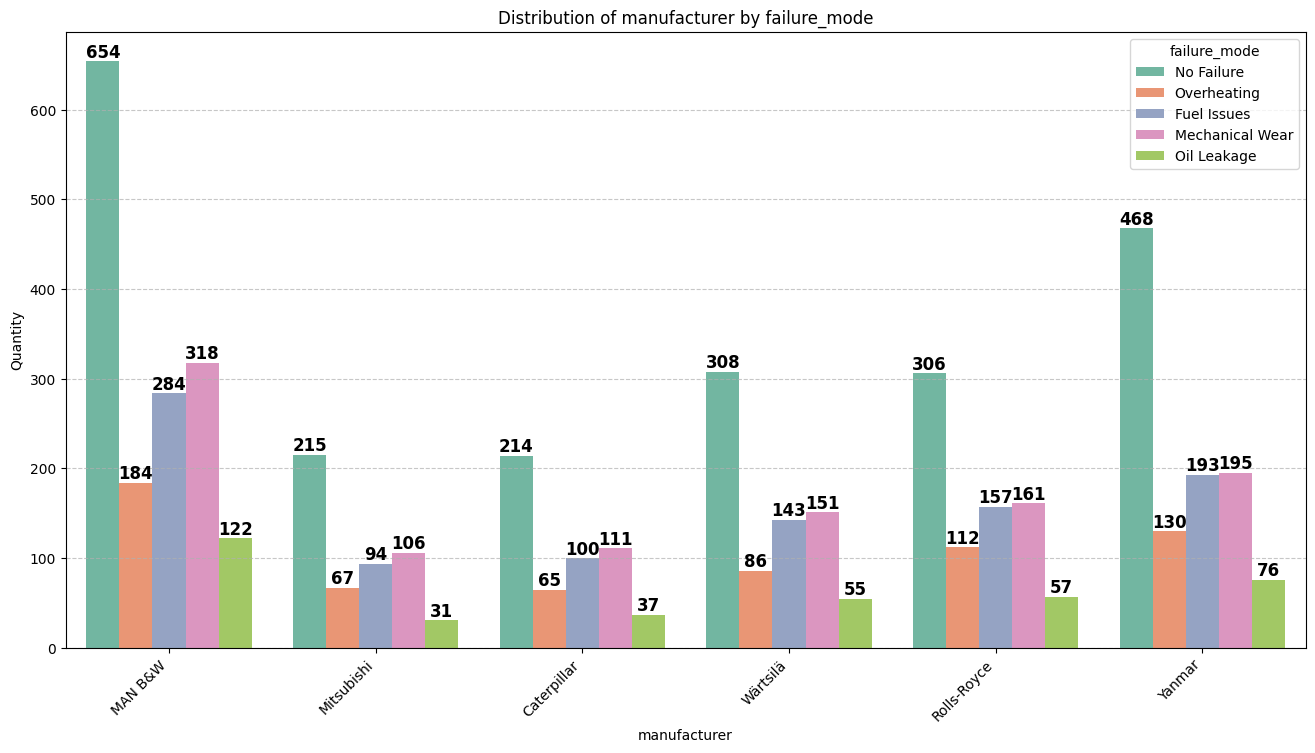

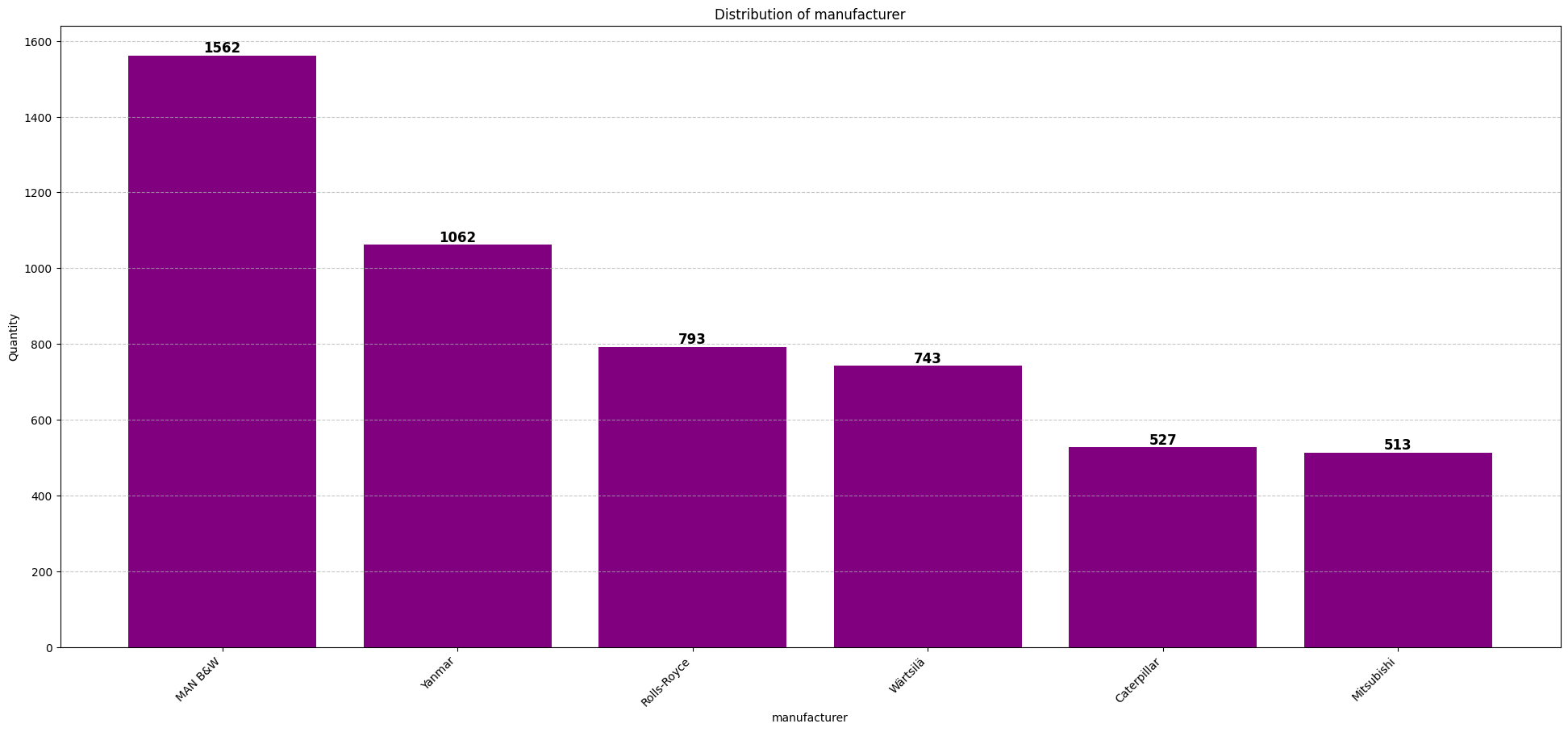

1.5 Analysis of Manufacturer Quantity Distributions

plot_bar_with_hue(data=data, column="manufacturer", hue="failure_mode")

plot_bar_with_counts(data, "manufacturer",color='purple')

We can conclude that MAN B&W largely dominates the dataset, representing the majority of records with 1562 occurrences, which may indicate greater adoption of its engines or a greater variety of models from this brand. Next, we have Yanmar with 1062 registrations, but already with a significant drop compared to MAN B&W.

Manufacturers such as Rolls-Royce , Wärtsilä, Caterpillar and Mitsubishi appear in smaller quantities, with 527 to 793 occurrences, which suggests a more specific presence in the dataset or less diversity of models.

When we look at failures, we can see that certain manufacturers are more associated with specific types of problems. MAN B&W, for example, presents faults such as Mechanical Wear (318 occurrences), Fuel Issues (284 occurrences) and Overheating (184 occurrences). Yanmar, the second most frequent, also records a considerable number of failures, mainly Mechanical Wear (195 occurrences), Fuel Issues (193 occurrences) and Overheating (130 occurrences).

This suggests that certain manufacturers may be more prone to specific failures, which could be indicative of specific engine characteristics or different operating conditions.

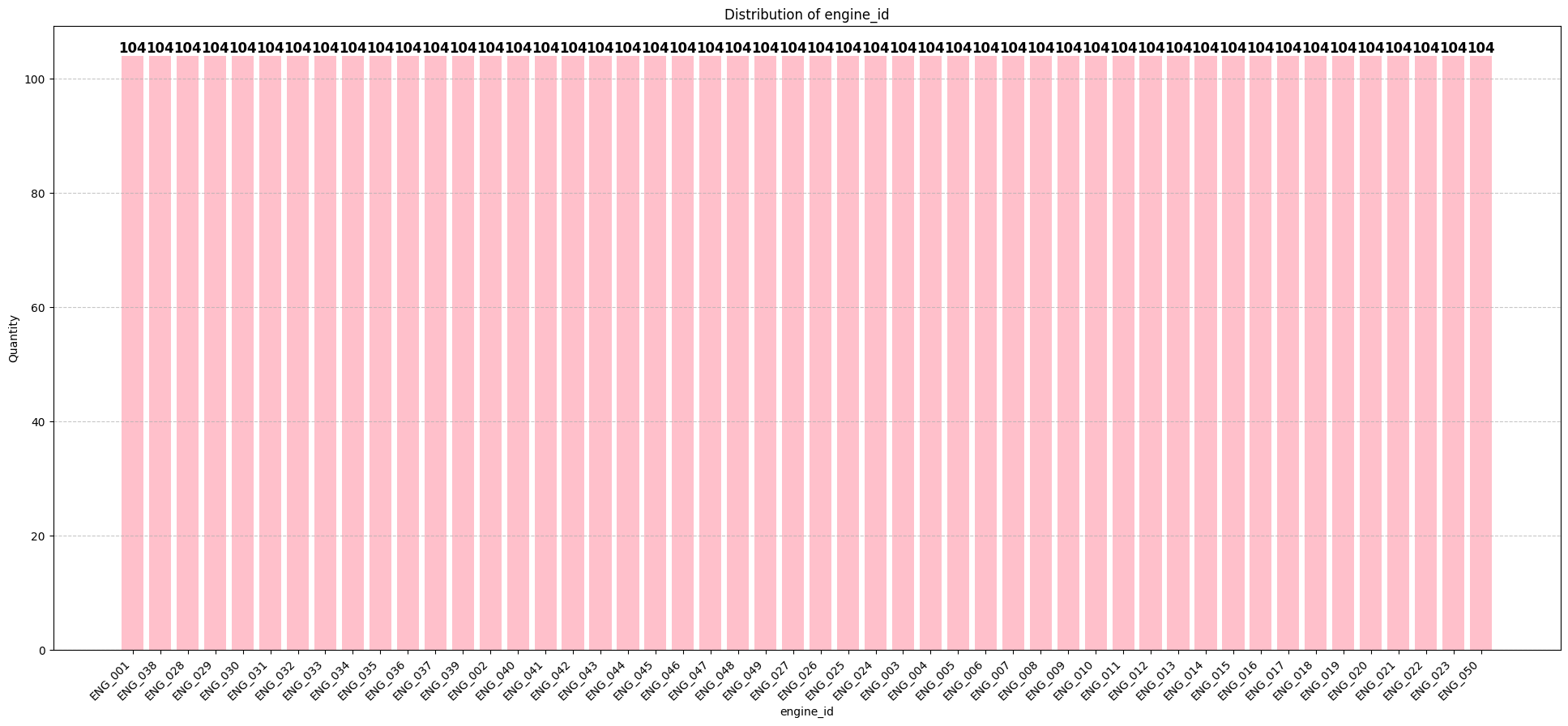

1.6 Analysis of Engine Quantity Distributions

plot_bar_with_counts(data, "engine_id", color='pink')

1.6.1 Uniform Distribution:

- The distribution of engine_ids is completely uniform, with each engine (from ENG_001 to ENG_050) having exactly 104 records. This indicates that the dataset was structured in such a way that each engine has the same number of records, which can be useful to ensure an equitable analysis of the engines in the dataset.

1.6.2 Possible Indicator of Engine Diversity:

- The fact that there are 50 different engine IDs, with the same number of records, suggests a diversity of engines in the dataset. This can be interesting for modeling, as the model can learn to generalize the characteristics of different types of engines.

1.7 Descriptive Statistical Analysis

Considering that there are differences in the engine profiles, to perform the descriptive statistical analysis, we will group the engines by engine type (engine_type). This way, we will be able to analyze the variables according to each type of engine, identifying specific patterns for each category.

# Grouping data by 'engine_type' grouped = data.groupby('engine_type') # Iterating through each 'engine_type' group and applying describe() for engine, group in grouped: print(f"Descriptive statistics for the engine {engine}:") display(group.describe()) print("\n" + "="*50 + "\n")

Descriptive statistics for the engine 2-stroke Low-Speed:

| Statistic | Engine Temp | Oil Pressure | Fuel Consumption | Vibration Level | RPM | Engine Load | Coolant Temp | Exhaust Temp | Running Period | Fuel Consumption per Hour |

|---|---|---|---|---|---|---|---|---|---|---|

| Count | 796.000000 | 796.000000 | 796.000000 | 796.000000 | 796.000000 | 796.000000 | 796.000000 | 796.000000 | 796.000000 | 796.000000 |

| Mean | 85.162926 | 7.289004 | 3932.811955 | 3.737143 | 1500.423723 | 50.046510 | 84.956753 | 449.816354 | 84.110651 | 116.325764 |

| Std | 7.104492 | 0.753409 | 2537.696784 | 0.356628 | 183.740580 | 17.523761 | 7.281260 | 1.350857 | 50.047411 | 81.261187 |

| Min | 66.228654 | 5.104294 | 1000.000000 | 2.628596 | 779.782979 | 20.056605 | 70.000000 | 433.126998 | 0.026501 | 100.000000 |

| 25% | 79.945180 | 6.703343 | 1793.669448 | 3.495721 | 1382.257315 | 34.907655 | 79.511771 | 450.000000 | 39.518859 | 100.000000 |

| 50% | 85.095806 | 7.501076 | 3387.200941 | 3.739999 | 1502.306758 | 49.660860 | 84.847404 | 450.000000 | 84.045377 | 100.000000 |

| 75% | 90.007971 | 8.000000 | 5660.098061 | 3.982576 | 1629.363548 | 65.718762 | 90.212482 | 450.000000 | 128.318703 | 100.000000 |

| Max | 104.755546 | 8.000000 | 12157.288286 | 4.766604 | 2055.992725 | 79.973462 | 100.000000 | 450.000000 | 167.909123 | 800.000000 |

Descriptive statistics for the engine 2-stroke Medium-Speed:

| Statistic | engine_temp | oil_pressure | fuel_consumption | vibration_level | rpm | engine_load | coolant_temp | exhaust_temp | running_period | fuel_consumption_per_hour |

|---|---|---|---|---|---|---|---|---|---|---|

| count | 1529.000 | 1529.000 | 1529.000 | 1529.000 | 1529 | 1529.000 | 1529.000 | 1529.000 | 1529.000 | 1529.000 |

| mean | 85.015 | 7.281 | 3970.649 | 3.765 | 1499 | 49.835 | 85.004 | 449.851 | 85.409 | 115.867 |

| std | 7.223 | 0.756 | 2462.943 | 0.363 | 209 | 17.133 | 7.504 | 1.224 | 48.743 | 80.044 |

| min | 64.628 | 5.000 | 1000.000 | 2.500 | 762 | 20.067 | 70.000 | 426.124 | 0.042 | 100.000 |

| 25% | 79.539 | 6.724 | 1877.587 | 3.524 | 1359 | 34.928 | 79.610 | 450.000 | 42.729 | 100.000 |

| 50% | 85.190 | 7.483 | 3486.633 | 3.769 | 1494 | 50.315 | 84.883 | 450.000 | 87.375 | 100.000 |

| 75% | 90.139 | 8.000 | 5704.353 | 4.018 | 1641 | 64.246 | 90.208 | 450.000 | 128.045 | 100.000 |

| max | 106.217 | 8.000 | 11597.795 | 4.904 | 2206 | 79.983 | 100.000 | 450.000 | 167.857 | 800.000 |

Descriptive statistics for the engine 4-stroke High-Speed:

| Statistic | engine_temp | oil_pressure | fuel_consumption | vibration_level | rpm | engine_load | coolant_temp | exhaust_temp | running_period | fuel_consumption_per_hour |

|---|---|---|---|---|---|---|---|---|---|---|

| count | 1548.000 | 1548.000 | 1548.000 | 1548.000 | 1548 | 1548.000 | 1548.000 | 1548.000 | 1548.000 | 1548.000 |

| mean | 84.960 | 7.279 | 3872.838 | 3.740 | 1492 | 49.473 | 84.836 | 449.790 | 82.932 | 117.346 |

| std | 7.264 | 0.745 | 2385.983 | 0.370 | 208 | 17.451 | 7.472 | 1.451 | 48.368 | 88.570 |

| min | 63.358 | 5.000 | 1000.000 | 2.500 | 733 | 20.036 | 70.000 | 429.901 | 0.052 | 100.000 |

| 25% | 79.941 | 6.724 | 1888.066 | 3.496 | 1348 | 33.764 | 79.620 | 450.000 | 41.115 | 100.000 |

| 50% | 84.806 | 7.499 | 3422.351 | 3.741 | 1490 | 49.556 | 84.695 | 450.000 | 82.379 | 100.000 |

| 75% | 90.222 | 8.000 | 5407.048 | 3.998 | 1633 | 64.465 | 90.379 | 450.000 | 125.912 | 100.000 |

| max | 104.856 | 8.000 | 11597.686 | 4.982 | 2175 | 79.901 | 100.000 | 450.000 | 167.773 | 800.000 |

Descriptive statistics for the engine 4-stroke Medium-Speed:

| Statistic | engine_temp | oil_pressure | fuel_consumption | vibration_level | rpm | engine_load | coolant_temp | exhaust_temp | running_period | fuel_consumption_per_hour |

|---|---|---|---|---|---|---|---|---|---|---|

| count | 1327.000 | 1327.000 | 1327.000 | 1327.000 | 1327 | 1327.000 | 1327.000 | 1327.000 | 1327.000 | 1327.000 |

| mean | 85.198 | 7.280 | 3978.232 | 3.738 | 1497 | 49.974 | 85.214 | 449.858 | 83.734 | 115.446 |

| std | 7.335 | 0.748 | 2414.796 | 0.372 | 201 | 17.453 | 7.563 | 1.173 | 49.146 | 77.517 |

| min | 60.525 | 5.000 | 1000.000 | 2.500 | 865 | 20.001 | 70.000 | 426.829 | 0.238 | 100.000 |

| 25% | 80.034 | 6.730 | 1963.813 | 3.490 | 1366 | 35.393 | 79.521 | 450.000 | 41.118 | 100.000 |

| 50% | 85.069 | 7.467 | 3502.965 | 3.731 | 1502 | 50.142 | 85.449 | 450.000 | 82.340 | 100.000 |

| 75% | 90.582 | 8.000 | 5656.639 | 3.984 | 1638 | 65.530 | 90.714 | 450.000 | 126.574 | 100.000 |

| max | 107.358 | 8.000 | 12672.543 | 5.000 | 2132 | 79.965 | 100.000 | 450.000 | 167.987 | 800.000 |

1.7.1 Comparison of Means

-

The average of the main variables presents small variations between engines:

-

Engine temperature: Similar average values (~85°C), with small variations.

-

Oil pressure: Average consistent around 7.28-7.29, indicating stability in this parameter.

-

Fuel consumption (fuel_consumption): Average values slightly higher in medium-sized engines (~3970) and lower in high-speed engines (~3872).

-

Vibration level: Average values between 3.73 and 3.76, with small differences.

-

RPM: Average close to 1500 RPM for all engines.

-

Engine load (engine_load): Similarity in average values (~50), indicating that the engines operate at similar loads.

1.7.2. Comparison of Dispersions (Standard Deviation - std)

- Engine temperature: Close standard deviations (~7°C), indicating a moderate variation in the data.

- Oil pressure: Low variation (~0.75), showing stable behavior between engines.

- Fuel consumption: High variation, especially in Low-Speed engines, indicating a greater range between minimum and maximum values.

- Vibration level: Small variation (~0.36), showing consistent behavior.

- RPM: Greater variation in Medium-Speed and High-Speed engines, possibly due to operational adjustments.

1.7.3. Comparison of Minimum and Maximum

- The 4-stroke Medium-Speed engine has the lowest minimum temperature (60.52°C) and the highest maximum temperature (107.35°C), indicating a greater operating range.

- The 2-stroke Low-Speed engine has the lowest minimum (779) and maximum (2055) RPM, suggesting a smaller range of variation compared to the High-Speed engines (732–2175).

- Oil pressure has an upper limit of 8.0 for all engines.

- Fuel consumption per hour varies between 100 and 800 for all engines, but the dispersion is greater in the 4-stroke Medium-Speed engine, which reaches 12672.54 in total consumption.

1.7.4. Key Insights

- Low-Speed and Medium-Speed 2-stroke engines have higher fuel consumption, possibly due to their efficiency under heavier loads.

- 4-stroke High-Speed engines have a slightly lower consumption, suggesting greater energy efficiency for high-speed operations.

- Medium-Speed engines show greater temperature variation, which may indicate a greater need for thermal monitoring.

- The vibration level is stable across all engines, without major differences between categories.

The four engine types, despite being from different manufacturers, exhibit similar behavior in terms of temperature, oil pressure, RPM, and vibration. However, Low-Speed and Medium-Speed engines consume more fuel, whereas High-Speed engines operate with lower relative fuel consumption but experience greater temperature variation.

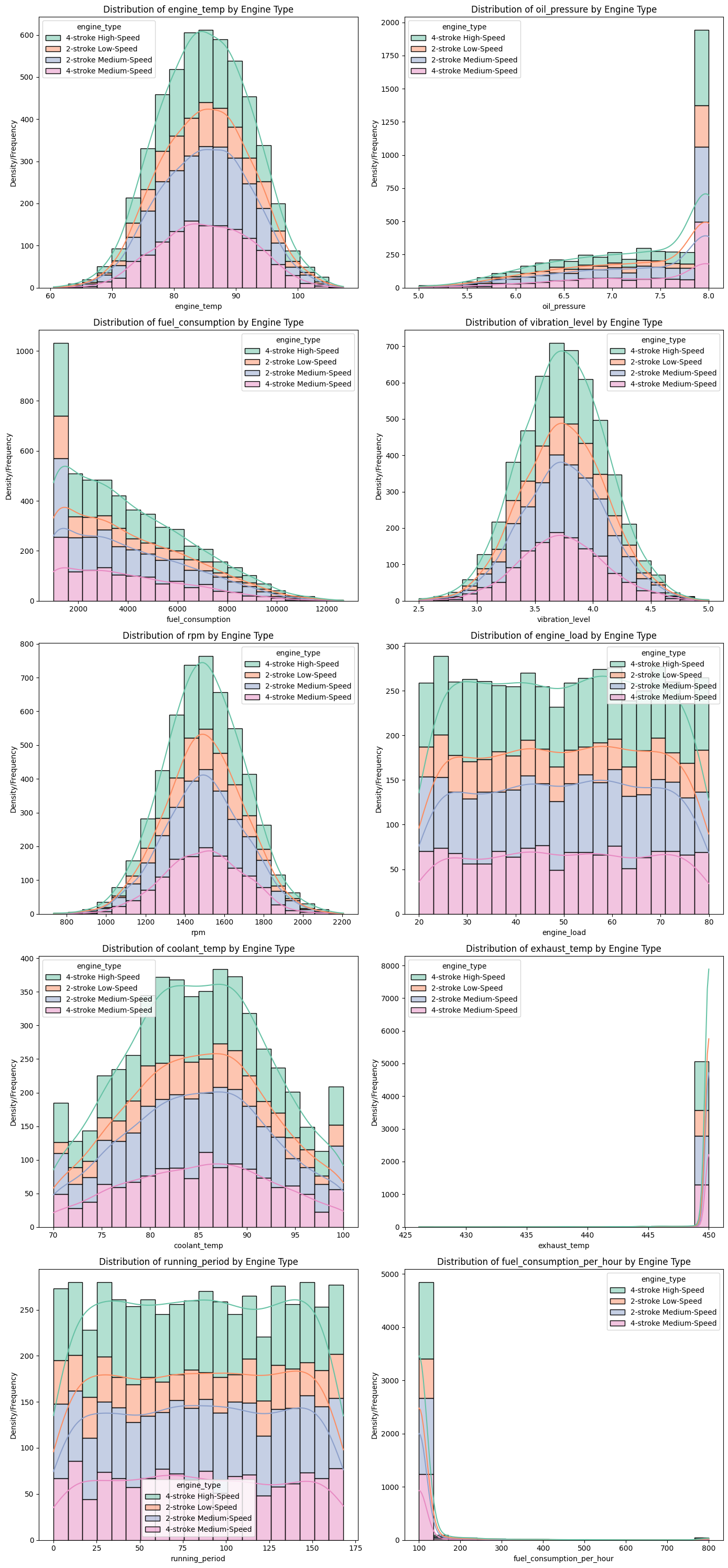

1.8 Analysis of Distribution and Density Curve by Motor

To better understand the behavior of different engines, we analyzed the distribution of their main operational variables, such as temperature, oil pressure, RPM and vibration. Additionally, we use density curves to visualize patterns and identify possible differences between engine types. This analysis can provide insights into fuel consumption, energy efficiency and thermal variations, helping to optimize performance and predict failures.

def plot_histograms_with_kde(data, variables): """ Plots histograms with the density curve (KDE) for several variables, grouped by engine type. Args: - data: DataFrame with the data. - variables: List of variables (columns) to be analyzed. """ #Setting the number of subgraphs n = len(variables) # Creating the figure with multiple subgraphs fig, axes = plt.subplots(nrows=(n // 2) + (n % 2), ncols=2, figsize=(14, 6 * ((n // 2) + (n % 2)))) axes = axes.flatten() # Flatten for easy indexing for i, variable in enumerate(variables): sns.histplot(data=data, x=variable, hue='engine_type', kde=True, multiple='stack', bins=20, palette='Set2', ax=axes[i]) # Adding title and labels axes[i].set_title(f'Distribution of {variable} by Engine Type') axes[i].set_xlabel(variable) axes[i].set_ylabel('Density/Frequency') # Adjusting the layout so as not to overlap the subgraphs plt.tight_layout() plt.show()

# Instantiating the function plot_histograms_with_kde(data, ['engine_temp', 'oil_pressure', 'fuel_consumption', 'vibration_level', 'rpm','engine_load', 'coolant_temp', 'exhaust_temp', 'running_period', 'fuel_consumption_per_hour'])

1.8.1 Distribution of Variables

Analysis of the distribution of variables can reveal important patterns in engine operation, allowing the identification of trends and distinct operational behaviors between different types of engines.

1.8.2 Variables with Normal Distribution (Bell Curve)

- Some variables follow a normal distribution, characterized by the concentration of most values around the mean and a symmetrical dispersion, with few extreme values.

engine_temp (Engine temperature)rpm (Revolutions Per Minute)vibration_level (Vibration Level)

High-Speed (4-stroke) engines tend to have higher average rpm and engine_temp values, operating in higher ranges compared to Low-Speed (2-stroke) engines, which operate at lower speeds. The vibration level, on the other hand, presents a similar distribution between the engines, but with greater dispersion in the High-Speed engines, indicating greater variability in the oscillations.

1.8.3 Variables with Asymmetric Distribution (Long Tail to the Right)

Some variables present positive skewness, that is, they have a long tail to the right. This means that although most values are concentrated in a certain range, there are some exceptionally high values that increase the average and widen the dispersion of the data.

fuel_consumption (Total Fuel Consumption)fuel_consumption_per_hour (Fuel Consumption Per Hour)engine_load (Engine Load - %)exhaust_temp (Exhaust Gas Temperature)

Low-Speed engines (2-stroke) have less variability in fuel consumption, with a more predictable and stable pattern. High-Speed engines (4-stroke) record extreme values of fuel consumption, reflecting intense operational peaks. This behavior may be associated with variations in engine load and power demands during operation.

In the next stage, a detailed analysis will be carried out to check the presence of outliers in the variables in our dataset, which may indicate atypical behaviors or measurement errors that may affect the analysis models.

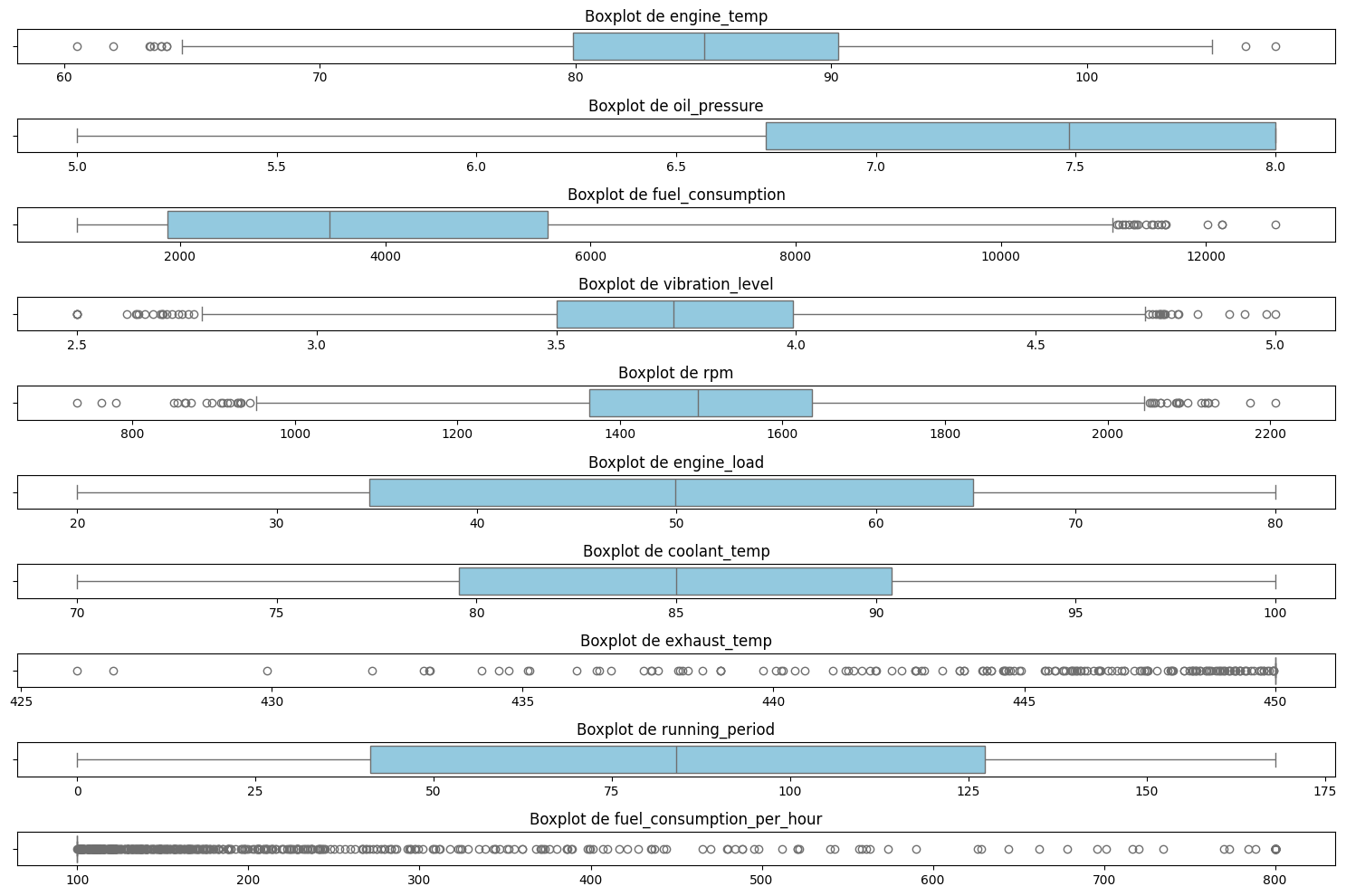

def plot_boxplots(df, columns, figsize=(15, 10)): """ Plots boxplots for each specified numeric variable. Parameters: df (pd.DataFrame): DataFrame containing the data. columns (list): List of numeric columns to be plotted. figsize (tuple): Size of the figure (width, height). """ num_vars = len(columns) fig, axes = plt.subplots(nrows=num_vars, ncols=1, figsize=figsize) for i, col in enumerate(columns): sns.boxplot(data=df, x=col, ax=axes[i], color='skyblue') axes[i].set_title(f'Boxplot de {col}') axes[i].set_xlabel('') plt.tight_layout() plt.show()

# List of numeric columns num_cols = [ 'engine_temp', 'oil_pressure','fuel_consumption', 'vibration_level', 'rpm', 'engine_load','coolant_temp', 'exhaust_temp', 'running_period', 'fuel_consumption_per_hour'] # Call the function to plot the boxplots plot_boxplots(data, num_cols)

By analyzing the boxplots of the engines above, it is possible to identify the presence of outliers in the following variables:

engine_temp(Engine temperature)fuel_consumption(Fuel consumption)fuel_consumption_per_hour(Fuel consumption per hour)exhaust_temp(Exhaust temperature)vibration_level(Vibration level)rpm(Revolutions per minute)

The presence of outliers may be associated with engine failure conditions, indicating atypical behaviors that may reflect operational problems. However, it is also possible that these outliers occur due to profile differences between engine types, such as high-speed and low-speed engines, which have different operating characteristics. Therefore, it is important to further investigate whether these extreme values are related to specific faults or whether they are simply a reflection of differences between engines.

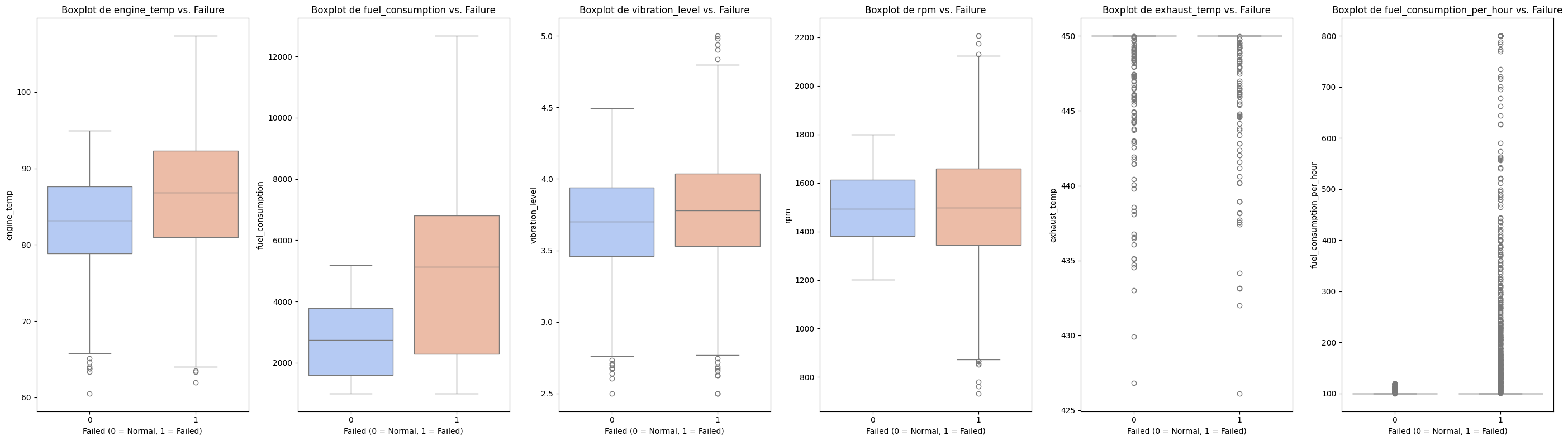

To investigate this hypothesis, we created an auxiliary variable called Failure_Binary. This variable has the value 0 for cases in which there is no failure and the value 1 for cases with failure. With this, we can compare the behavior of variables with and without outliers in relation to engine failures.

# Create the failure binary variable data['Failure_Binary'] = np.where(data['failure_mode'] == 'No Failure', 0, 1)

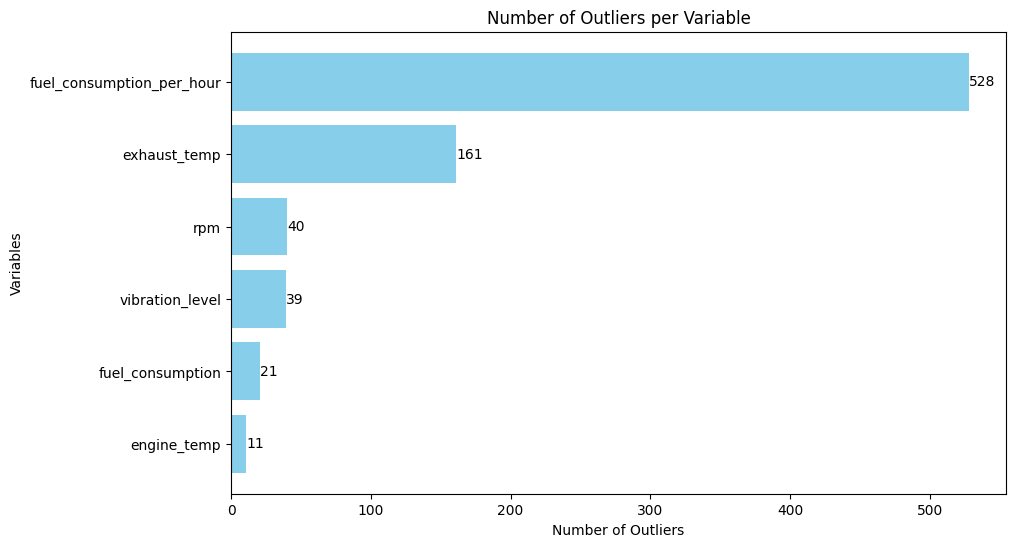

def detect_outliers(df, col): Q1 = df[col].quantile(0.25) Q3 = df[col].quantile(0.75) IQR = Q3 - Q1 lower_bound = Q1 - 1.5 * IQR upper_bound = Q3 + 1.5 * IQR return df[(df[col] < lower_bound) | (df[col] > upper_bound)] # Select relevant variables for outlier analysis variables = ['engine_temp', 'fuel_consumption', 'vibration_level', 'rpm', 'exhaust_temp','fuel_consumption_per_hour'] # Detect outliers for each variable outliers_dict = {var: detect_outliers(data, var) for var in variables} def plot_outliers_bar_chart(outliers_dict): # Initialize lists for variables and outlier quantities variables_list = [] outliers_count_list = [] # Fill the lists with data from the outlier dictionary for var, outliers_df in outliers_dict.items(): variables_list.append(var) outliers_count_list.append(len(outliers_df)) # Create the bar chart plt.figure(figsize=(10,6)) bars = plt.barh(variables_list, outliers_count_list, color='skyblue') # Add title and labels to axes plt.title('Number of Outliers per Variable') plt.xlabel('Number of Outliers') plt.ylabel('Variables') # Add the values to the top of each bar for bar in bars: plt.text(bar.get_width(), bar.get_y() + bar.get_height()/2, str(int(bar.get_width())), va='center', ha='left', color='black') # Display the graph plt.show()

# Now, to plot the graph with the values at the top of the bars, just call the function plot_outliers_bar_chart(outliers_dict)

Among the variables analyzed, fuel_consumption_per_hour presented the largest number of outliers. Now, let's investigate the behavior of variables under failure and non-failure conditions by plotting boxplots for each variable against the Failure_Binary column:

def plot_boxplots_for_variables(variables, data, title_prefix='Boxplot de'): """ Plots the boxplots of the variables against the 'Failure_Binary' column in a single plot. Parameters: - variables: List with the names of the variables to be analyzed. - data: DataFrame containing the data. - title_prefix: Prefix for the chart title. """ # Graphics configuration plt.figure(figsize=(28, 8)) # Loop to create boxplots for each variable for i, var in enumerate(variables, 1): plt.subplot(1, len(variables), i) sns.boxplot(x='Failure_Binary', y=var, data=data, palette="coolwarm") plt.title(f'{title_prefix} {var} vs. Failure') plt.xlabel('Failed (0 = Normal, 1 = Failed)') plt.ylabel(var) # Adjusts the layout to ensure graphics do not overlap plt.tight_layout() plt.show()

# List of variables for analysis variables = ['engine_temp', 'fuel_consumption', 'vibration_level', 'rpm', 'exhaust_temp','fuel_consumption_per_hour'] # Call the function to generate the boxplots plot_boxplots_for_variables(variables, data)

The boxplots reveal significant differences in the behavior of variables between fault conditions and normal operation. This suggests that the outliers may be directly associated with engine failures.

To validate the hypothesis that outliers are not necessarily related to failures, we applied the Mann-Whitney U statistical test. This test allows comparing the distributions of variables between groups with and without failure, evaluating whether there are statistically significant differences.

Below are the results:

def test_statistical_difference(data, variables): for var in variables: normal = data[data['Failure_Binary'] == 0][var] failure = data[data['Failure_Binary'] == 1][var] stat, p_value = mannwhitneyu(normal, failure, alternative='two-sided') print(f"{var}: U={stat:.2f}, p-valor={p_value:.5f}") if p_value < 0.05: print(f" -> Statistically significant difference between normal and failure cases!\n") else: print(f" -> There is not enough evidence to conclude that there is a difference.\n")

variables = ['engine_temp', 'fuel_consumption', 'vibration_level', 'rpm', 'exhaust_temp','fuel_consumption_per_hour'] test_statistical_difference(data, variables)

engine_temp: U=2361907.00, p-valor=0.00000

-> Statistically significant difference between normal and failure cases!

fuel_consumption: U=1853117.00, p-valor=0.00000

-> Statistically significant difference between normal and failure cases!

vibration_level: U=2862284.50, p-valor=0.00000

-> Statistically significant difference between normal and failure cases!

rpm: U=3272684.00, p-valor=0.81185

-> There is not enough evidence to conclude that there is a difference.

exhaust_temp: U=3233628.00, p-valor=0.00123

-> Statistically significant difference between normal and failure cases!

fuel_consumption_per_hour: U=2891093.50, p-valor=0.00000

-> Statistically significant difference between normal and failure cases!

1.8.4 Variables with Statistically Significant Difference:

-

Engine Temperature (

engine_temp): The difference between failing engines and normal engines is statistically significant, suggesting that variations in temperature may be directly associated with failures. -

Total Fuel Consumption (

fuel_consumption): There is a significant discrepancy between the two groups, indicating that failures can directly affect fuel consumption. -

Vibration Level (

vibration_level): Engine vibration presents significant differences, which may indicate that failing engines exhibit anomalous vibration patterns. -

Exhaust Gas Temperature (

exhaust_temp): The statistical difference suggests that the thermal exhaust of engines can be an important indicator for monitoring failures. -

Fuel Consumption per Hour (

fuel_consumption_per_hour): Just like total consumption, this variable also presents differences between normal and failing engines, reinforcing the relationship between failure and variation in energy consumption.

1.8.5 Variable Without Statistically Significant Difference:

- Revolutions per Minute (

rpm): The high p-value indicates that there is not enough evidence to state that there is a significant difference in the behavior of this variable between normal and failing engines. This suggests that engine speed may not be a reliable indicator of failure, or that failures may occur in different speed ranges without a clear pattern.

# Removing the Failure_Binary column created to help solve the problem: data = data.drop(columns='Failure_Binary')

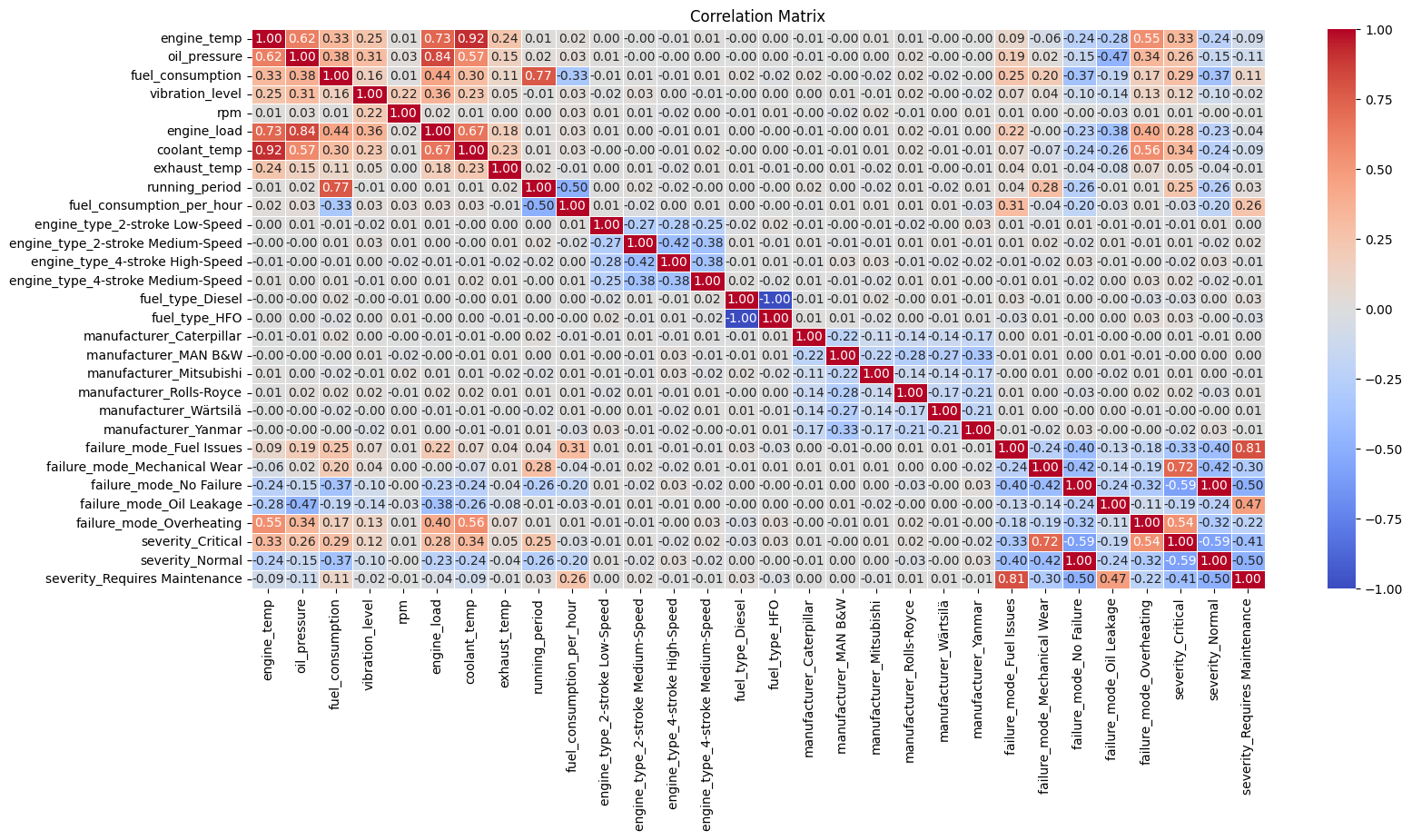

1.9 Correlation Analysis

Correlation analysis is a fundamental step to identify relationships between variables in the data set. The objective is to verify which variables present association patterns, which can be useful to detect possible indicators of engine failure.

# Step 1: Remove unneeded columns: data_one_hot_encode = data.drop(columns=['engine_id', 'timestamp']) # Step 2: Apply One-Hot Encoding to categorical variables (strings) categorical_columns = data_one_hot_encode.select_dtypes(include=['object']).columns # Step 3: Applying One-Hot Encoding without removing the first category data_one_hot_encode = pd.get_dummies(data_one_hot_encode, columns=categorical_columns, drop_first=False) # Step 4: Convert True/False to 1/0 data_one_hot_encode = data_one_hot_encode.astype(int)

# Step 5: Calculate the correlation matrix correlation_matrix = data_one_hot_encode.corr(method='spearman') # Step 6: Plot the correlation matrix plt.figure(figsize=(18, 8)) sns.heatmap(correlation_matrix, annot=True, cmap='coolwarm', fmt='.2f', linewidths=0.5) plt.title('Correlation Matrix') plt.show()

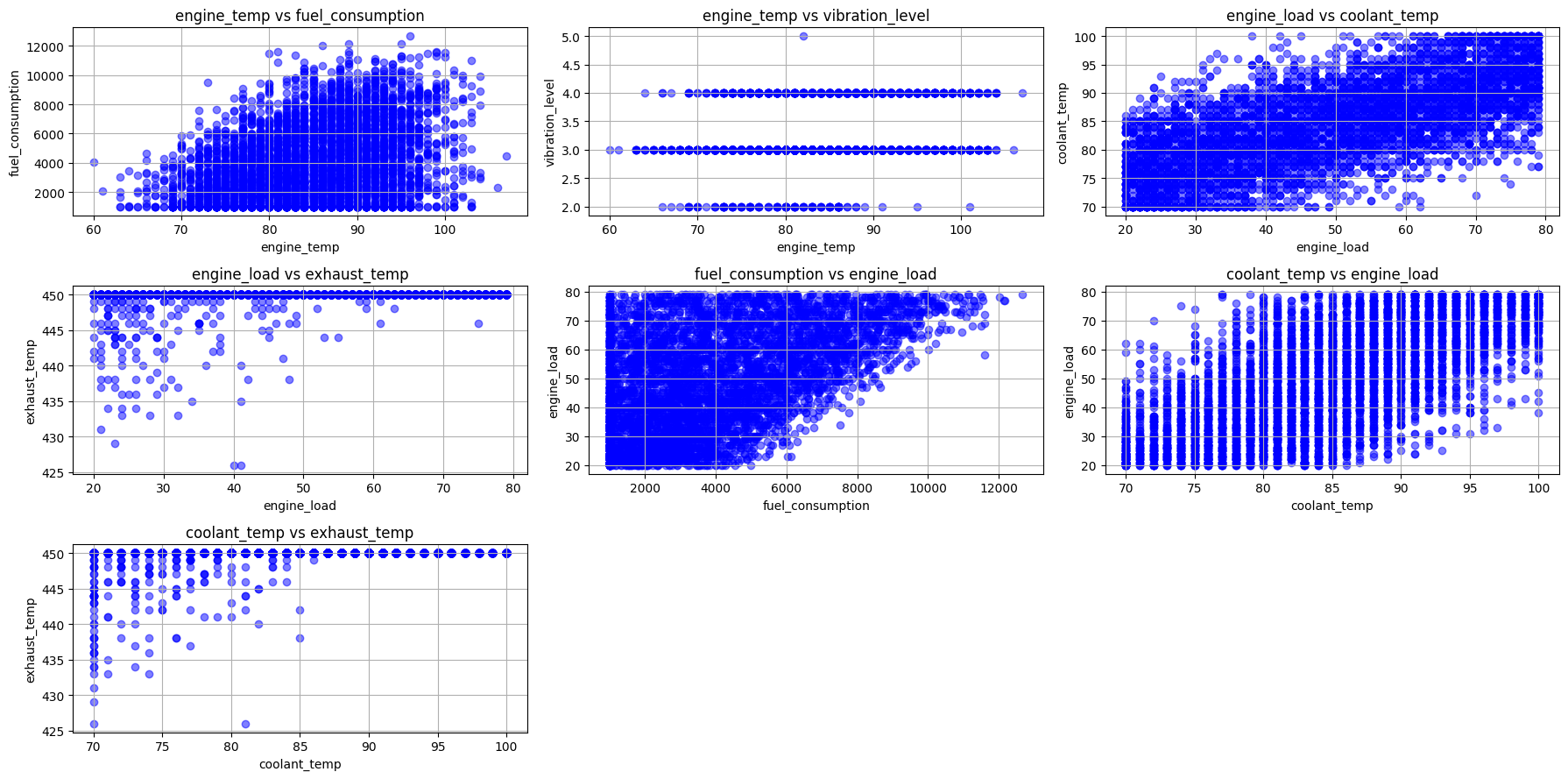

From the correlation matrix presented in this way, it is possible to check which variables have the greatest correlation with each other, and which would be the potential features that have a correlation with engine failures. In order to explore these correlations, a function will be created so that we can plot and not only analyze the strength of correlation but also try to evaluate the type of correlation.

def plot_scatter(ax, x, y, xlabel, ylabel, title,): """Helper function to create scatter plots""" ax.scatter(x, y, color='blue', alpha=0.5, label='Data') ax.set_xlabel(xlabel) ax.set_ylabel(ylabel) ax.set_title(title) ax.grid(True) def plot_correlations(data, column_pairs, ncols=4, figsize=(16, 8)): """ Generates scatter plots for specified column pairs Parameters: data (DataFrame): DataFrame with the data column_pairs (list): List of tuples with column pairs to plot [(x1, y1), (x2, y2), ...] ncols (int): Number of chart columns per row figsize (tuple): Size of the figure (width, height) """ n_pairs = len(column_pairs) nrows = (n_pairs + ncols - 1) // ncols # Calculate the required number of lines fig, axes = plt.subplots(nrows, ncols, figsize=figsize) axes = axes.flatten() # Transform the axis matrix into a flat list # Plot each pair of columns for i, (x_col, y_col) in enumerate(column_pairs): plot_scatter(axes[i], data[x_col], data[y_col], x_col, y_col, f'{x_col} vs {y_col}') # Disable unused axes for j in range(i+1, len(axes)): axes[j].axis('off') plt.tight_layout() plt.show()

Strong Correlations

-

engine_temp and coolant_temp → 0.92

-

engine_temp and engine_load → 0.73

-

oil_preasure and engine_load → 0.84

-

fuel_consumption and running_period → 0.77

-

severity_requires maintenance and failure_mode_Fuel Issues → 0.81

-

failure_mode_Mechanical Wear and severity_normal → 0.72

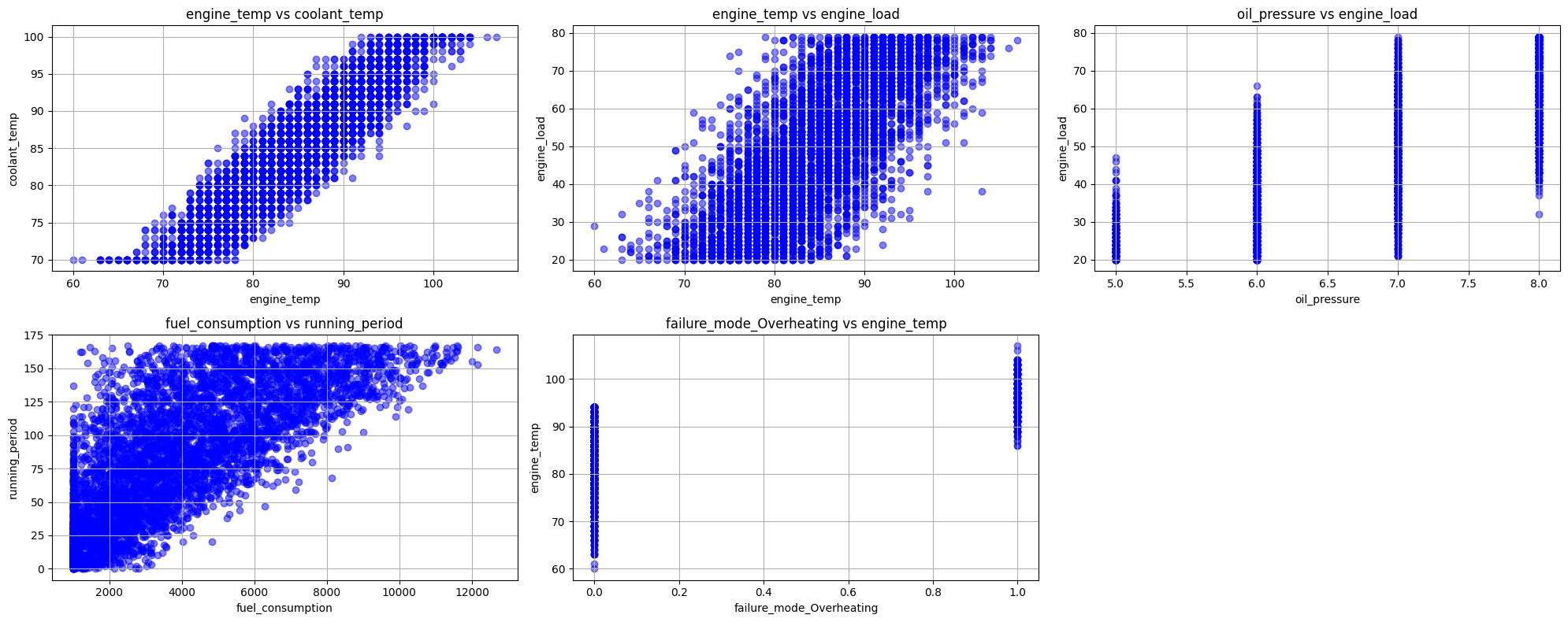

# List of column pairs to correlate strong_correlation_pairs = [('engine_temp','coolant_temp'), ('engine_temp', 'engine_load'), ('oil_pressure', 'engine_load'), ('fuel_consumption', 'running_period'),\ ('failure_mode_Overheating', 'engine_temp')] # Chamada da função plot_correlations(data_one_hot_encode, column_pairs=strong_correlation_pairs, ncols=3, figsize=(20, 8))

1.9.1 Relationship Between Engine Temperature and Coolant Temperature

- There is an almost linear positive relationship between engine temperature (

engine_temp) and coolant temperature (coolant_temp). - This suggests that the cooling system is responding proportionally to changes in engine temperature, ensuring optimal thermal management.

- Significant deviations from this trend (e.g.,

engine_temprising sharply whilecoolant_tempremains constant) could indicate cooling system issues, such as a faulty radiator, an inefficient water pump, or sensor inaccuracies.

1.9.2 Engine Temperature vs. Engine Load

- There is a clear positive correlation: as engine load (

engine_load) increases, engine temperature (engine_temp) also tends to rise. - This is expected, as higher loads require more power output, generating additional heat.

- However, if an engine operates at low loads but exhibits high temperatures, this may indicate thermal inefficiency, poor lubrication, or cooling system malfunctions.

1.9.3 Oil Pressure vs. Engine Load

- Oil pressure (

oil_pressure) values appear to be concentrated at a few discrete levels, suggesting that the oil pressure regulation system maintains it within specific ranges. - The system may be designed to stabilize pressure regardless of variations in engine load (

engine_load). - If oil pressure does not vary as expected (e.g., remains too low under high loads), this could indicate issues such as an oil pump failure, improper oil viscosity, or potential leaks.

1.9.4 Fuel Consumption vs. Running Period

- There is a positive yet nonlinear relationship between fuel consumption (

fuel_consumption) and running time (running_period). Initially, fuel consumption increases rapidly but then stabilizes. - New or recently started engines may consume more fuel at first to reach optimal operating temperature. Over time, fuel consumption tends to level off as thermal efficiency improves.

- A deeper analysis could help identify engines consuming more fuel than expected for a given operating period, potentially indicating inefficiencies, leaks, or suboptimal combustion.

1.9.5 Failure Mode (Overheating) vs. Engine Temperature

- Engines that experienced overheating failures (

failure_mode_Overheating = 1) show significantly higher temperatures than normal engines (failure_mode_Overheating = 0). - This confirms that excessive temperatures are a critical factor in engine failures.

- A critical threshold for

engine_tempcan be defined, above which the risk of overheating-related failures increases sharply. This threshold could be used for real-time alerts and predictive maintenance to prevent breakdowns.

Moderate Correlations:

| Moderate Positive Correlations (0.4 to 0.7) | Correlações Negativas Moderadas (-0.4 a -0.7) |

|---|---|

| engine_temp and oil_pressure → 0.62 | failure_mode_Oil Leakage and failure_mode_Overheating → -0.47 |

| oil_preasure and coolant_temp → 0.57 | failure_mode_Oil Leakage and severity_Critical → -0.50 |

| engine_load and coolant_temp → 0.67 | failure_mode_Oil Leakage and severity_Requires Maintenance → -0.50 |

| engine_load and exhaust_temp → 0.67 | failure_mode_Mechanical Wear and severity_Critical → -0.42 |

| fuel_consumption and engine_load → 0.44 | failure_mode_Mechanical Wear and severity_Normal → -0.40 |

| failure_mode_Overheating and severity_Critical → 0.54 | failure_mode_No Failure and severity_Critical → -0.59 |

| failure_mode_Overheating and severity_Requires Maintenance → 0.47 | failure_mode_No Failure and severity_Requires Maintenance → -0.59 |

| failure_mode_Overheating and severity_Normal → 0.56 |

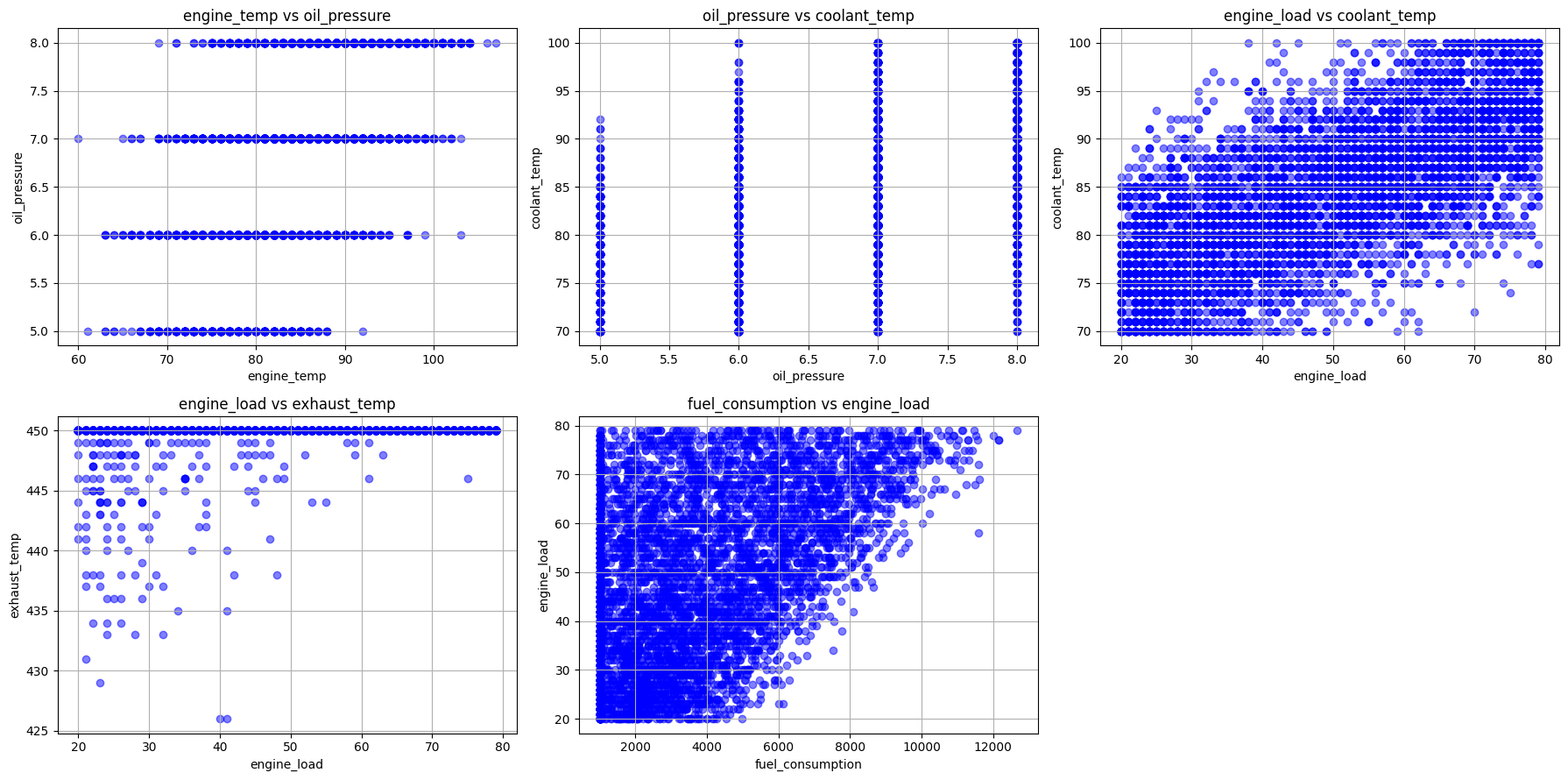

# List of column pairs to correlate moderate_correlation_pairs = [('engine_temp','oil_pressure'), ('oil_pressure', 'coolant_temp'), ('engine_load', 'coolant_temp'), ('engine_load', 'exhaust_temp'), ('fuel_consumption', 'engine_load') ] # Function call plot_correlations(data_one_hot_encode, column_pairs=moderate_correlation_pairs , ncols=3, figsize=(18, 9))

1.9.6 Engine Temperature (engine_temp) and Oil Pressure (oil_pressure)

- This confirms the trend observed in the graph: as engine temperature increases, oil pressure also tends to rise. This may indicate a thermal effect on oil viscosity or a response from the engine lubrication system.

1.9.7 Oil Pressure (oil_pressure) and Coolant Temperature (coolant_temp)

- This result indicates that engines operating with higher oil pressure tend to have higher coolant temperatures. This may be related to the efficiency of the lubrication and cooling system.

1.9.8 Engine Load (engine_load) and Coolant Temperature (coolant_temp)

- The graph already indicated this positive relationship. Engines under higher load generate more heat, demanding more from the cooling system.

1.9.9 Engine Load (engine_load) and Exhaust Temperature (exhaust_temp)

- This correlation reinforces that as engine load increases, exhaust gas temperature also rises. This behavior is expected, as more intense combustion generates greater thermal dissipation.

1.9.10 Fuel Consumption (fuel_consumption) and Engine Load (engine_load)

- This relationship was evident in the graph. Fuel consumption increases as engine load rises, which is expected in internal combustion engines.

1.9.11 Failure Mode Overheating (failure_mode_Overheating) and Critical Severity (severity_Critical)

- This suggests that when overheating occurs, there is a moderate tendency for it to result in critical failures. This reinforces the need to monitor engine temperature.

1.9.12 Failure Mode Overheating (failure_mode_Overheating) and Requires Maintenance Severity (severity_Requires Maintenance)

- In some cases, overheating may not be critical but may indicate the need for maintenance.

1.9.13 Failure Mode Overheating (failure_mode_Overheating) and Normal Severity (severity_Normal)

- Interestingly, there is a moderate positive correlation between overheating and failures classified as normal. This may indicate that overheating does not always lead to critical problems, depending on its intensity and duration.

1.9.14 Oil Leakage Failure (failure_mode_Oil Leakage) and Overheating Failure (failure_mode_Overheating)

- This suggests that oil leaks rarely occur simultaneously with overheating, indicating that these failure modes do not have a direct relationship.

1.9.15 Oil Leakage Failure (failure_mode_Oil Leakage) and Critical Severity (severity_Critical)

- Oil leaks may be less likely to cause critical failures, possibly because they are detected before becoming severe.

1.9.16 Oil Leakage Failure (failure_mode_Oil Leakage) and Requires Maintenance Severity (severity_Requires Maintenance)

- This reinforces the idea that oil leaks are not among the main causes requiring immediate corrective maintenance.

1.9.17 Mechanical Wear Failure (failure_mode_Mechanical Wear) and Critical Severity (severity_Critical)

- This indicates that mechanical wear failures are not the main contributors to critical failures, possibly occurring gradually and predictably.

1.9.18 Mechanical Wear Failure (failure_mode_Mechanical Wear) and Normal Severity (severity_Normal)

- Mechanical wear seems to occur less frequently in scenarios considered normal.

1.9.19 No Failure Mode (failure_mode_No Failure) and Critical Severity (severity_Critical)

- The fewer failures occur, the lower the probability of a critical situation, which is intuitive.

1.9.20 No Failure Mode (failure_mode_No Failure) and Requires Maintenance Severity (severity_Requires Maintenance)

- This reinforces that when the system operates without failures, the need for corrective maintenance decreases.

Weak Correlations

| Weak Positive Correlations (0.2 to 0.4) | Weak Negative Correlations (-0.2 to -0.4) |

|---|---|

| engine_temp and fuel_consumption → 0.33 | fuel_consumption and failure_mode_No Failure → -0.24 |

| engine_temp and vibration_level → 0.31 | fuel_consumption and failure_mode_Oil Leakage → -0.28 |

| engine_temp and exhaust_temp → 0.24 | failure_mode_No Failure and severity_Critical → -0.24 |

| fuel_consumption and engine_load → 0.30 | failure_mode_No Failure and severity_Normal → -0.37 |

| coolant_temp and engine_load → 0.36 | failure_mode_No Failure and severity_Requires Maintenance → -0.26 |

| coolant_temp and exhaust_temp → 0.23 | failure_mode_Oil Leakage and severity_Critical → -0.24 |

| failure_mode_Fuel Issues and failure_mode_Mechanical Wear → 0.25 | failure_mode_Oil Leakage and severity_Normal → -0.32 |

| failure_mode_Fuel Issues and severity_Critical → 0.31 | failure_mode_Oil Leakage and severity_Requires Maintenance → -0.22 |

| failure_mode_Overheating and severity_Critical → 0.34 | failure_mode_Overheating and failure_mode_Mechanical Wear → -0.30 |

| failure_mode_Overheating and severity_Normal → 0.29 | failure_mode_Overheating and failure_mode_Oil Leakage → -0.24 |

| failure_mode_Overheating and severity_Requires Maintenance → 0.26 |

# List of column pairs to correlate weak_correlation_pairs = [('engine_temp','fuel_consumption'), ('engine_temp', 'vibration_level'), ('engine_load', 'coolant_temp'), ('engine_load', 'exhaust_temp'), ('fuel_consumption', 'engine_load'),\ ('coolant_temp', 'engine_load'), ('coolant_temp','exhaust_temp')] # Function call plot_correlations(data_one_hot_encode, column_pairs=weak_correlation_pairs, ncols=3, figsize=(18, 9))

1.9.11 Engine Temperature vs. Fuel Consumption

- There is a noticeable upward trend between engine temperature and fuel consumption. This may indicate that hotter engines consume more fuel, possibly due to increased power demand or reduced thermal efficiency at higher temperatures.

- However, significant data dispersion suggests that other factors also influence fuel consumption.

1.9.12 Engine Temperature vs. Vibration Level

- Engine vibration appears to be segmented into discrete values, which may indicate that the vibration sensor measures fixed levels rather than a continuous spectrum.

- There is no clear correlation between engine temperature and vibration level, suggesting that other factors may have a stronger influence on vibration.

1.9.13 Engine Load vs. Coolant Temperature

- There is a clear positive correlation where engines under higher loads tend to have higher coolant temperatures. This makes sense, as more demanding engine conditions generate more heat, requiring greater cooling capacity.

- Data dispersion increases as load rises, suggesting that at high loads, cooling efficiency may vary depending on engine conditions.

1.9.14 Engine Load vs. Exhaust Temperature

- Exhaust gas temperature appears to reach a maximum threshold of around 450°C. This may indicate an operational limit of the exhaust system, where temperature is controlled to prevent damage.

- At lower loads, there is greater variation in exhaust gas temperature, suggesting that the engine may operate in different thermal modes depending on demand.

1.9.15 Fuel Consumption vs. Engine Load

- The relationship is strongly positive, meaning that engines under higher loads require more fuel. The graph suggests a nonlinear pattern, where fuel consumption increases more rapidly at high loads.

- This can be explained by efficiency losses and increased mechanical resistance under heavy loads.

1.9.16 Coolant Temperature vs. Exhaust Temperature

- Exhaust gas temperature seems to reach a maximum limit regardless of increases in coolant temperature. This may indicate that the exhaust system has a thermal limit imposed by design, possibly to prevent overheating of the catalytic converter or other components.

By analyzing the results, we can observe that some variables exhibit a linear relationship with each other. However, no metric showed a strong correlation with any specific failure, except for engine_temp, which demonstrated a linear relationship with failure_mode_Overheating. This suggests that engine_temp could be a key variable in predicting this type of failure.

It is important to note that the correlation analysis used was linear. This means that while no strong correlations were identified between the failures and other variables, it does not necessarily imply that such relationships do not exist. Instead, the correlations may be more complex and non-linear in nature. To further investigate this possibility, an additional correlation analysis will be conducted using the chi-square method.

def analyze_categorical_numerical_relationships(data, target="failure_mode"): """ Analyzes the relationship between numeric variables and a categorical variable using: - Chi-Square (Chi²) for discretized variables - ANOVA (F-stat) for differences in means - Eta² to measure the strength of the association - Identification of the most influential failure mode in each variable Returns a DataFrame with the results ordered by the strength of the relationship. """ numeric_vars = data.select_dtypes(include=["number"]).columns.tolist() if target in numeric_vars: numeric_vars.remove(target) results = [] # Get all unique failure modes failure_modes = data[target].unique() for var in numeric_vars: # Create bins (quartiles) for Chi-Square data[f"{var}_binned"] = pd.qcut(data[var], q=4, duplicates="drop") # Chi-Square contingency_table = pd.crosstab(data[f"{var}_binned"], data[target]) chi2, p_chi2, _, _ = chi2_contingency(contingency_table) # ANOVA groups = [data[var][data[target] == cat] for cat in data[target].unique()] f_stat, p_anova = stats.f_oneway(*groups) if len(groups) > 1 else (np.nan, np.nan) # Eta² grand_mean = np.mean(data[var]) ss_between = sum(len(group) * (np.mean(group) - grand_mean) ** 2 for group in groups) ss_total = sum((data[var] - grand_mean) ** 2) eta_squared = ss_between / ss_total if ss_total > 0 else 0 # Calculate the average of each failure mode for the variable failure_impacts = data.groupby(target)[var].mean() # Create a line with the average for each failure mode mode_columns = {f"{mode}": failure_impacts.get(mode, np.nan) for mode in failure_modes} results.append({ "Variable": var, "Chi2": chi2, "p-value Chi2": p_chi2, "F-stat": f_stat, "p-value ANOVA": p_anova, "Eta²": eta_squared, **mode_columns # Add failure mode columns }) # Create Results DataFrame results_df = pd.DataFrame(results) # Sort by Eta² (relationship strength) results_df = results_df.sort_values(by="Eta²", ascending=False) return results_df

# Instantiating the function: df_results = analyze_categorical_numerical_relationships(data, target="failure_mode") display(df_results)

| Variable | Chi2 | p-value Chi2 | F-stat | p-value ANOVA | Eta² | No Failure | Overheating | Fuel Issues | Mechanical Wear | Oil Leakage |

|---|---|---|---|---|---|---|---|---|---|---|

| oil_pressure | 1878.3569 | 0.000000e+00 | 1054.0622 | 0.000000e+00 | 0.4480 | 7.2022 | 7.8772 | 7.6105 | 7.3491 | 5.6889 |

| coolant_temp | 2569.7718 | 0.000000e+00 | 966.5436 | 0.000000e+00 | 0.4267 | 82.8286 | 97.0233 | 85.8531 | 83.8252 | 78.0033 |

| engine_temp | 2511.2935 | 0.000000e+00 | 930.3677 | 0.000000e+00 | 0.4174 | 82.9502 | 96.3285 | 86.2125 | 84.0975 | 77.7481 |

| engine_load | 2221.5095 | 0.000000e+00 | 690.0428 | 0.000000e+00 | 0.3470 | 45.0061 | 68.2987 | 57.6422 | 49.6289 | 25.9987 |

| fuel_consumption | 1881.6409 | 0.000000e+00 | 454.5458 | 0.000000e+00 | 0.2593 | 2742.2302 | 5195.7473 | 5310.7801 | 4954.3623 | 2311.3887 |

| running_period | 1024.8120 | 8.670252e-212 | 154.2039 | 7.507213e-125 | 0.1061 | 68.7582 | 85.3004 | 88.1446 | 111.7049 | 82.6876 |

| vibration_level | 352.9032 | 3.422920e-68 | 101.5193 | 2.372852e-83 | 0.0725 | 3.6957 | 3.9084 | 3.8088 | 3.7838 | 3.5002 |

| fuel_consumption_per_hour | 0.0000 | 1.000000e+00 | 96.2357 | 4.153684e-79 | 0.0690 | 100.3316 | 116.2123 | 159.6435 | 112.3262 | 107.1112 |

| exhaust_temp | 0.0000 | 1.000000e+00 | 10.3783 | 2.267933e-08 | 0.0079 | 449.7849 | 450.0000 | 449.9333 | 449.8326 | 449.5189 |

| rpm | 296.6099 | 2.417450e-56 | 1.1919 | 3.121149e-01 | 0.0009 | 1496.1979 | 1503.1674 | 1502.0570 | 1496.8134 | 1477.3714 |

Based on the results presented by the correlation analysis between the numerical variables and the categorical variable failure_mode, we can draw some conclusions about the variables' ability to be used to make failure predictions reliably. Let's analyze the main points:

1.8.1 Analysis of Eta² Values (Association Strength)

- Eta² is a statistical measure that evaluates the strength of the association between numerical variables and a categorical variable (in this case, the failure modes). The higher the Eta² value, the stronger the relationship between the numerical variable and the failure mode variable. This measure helps us identify which variables may be most predictive of failure, and thus guide the development of more effective predictive models.

Variables with higher Eta² (high association strength):

-

oil_pressure (0.448):

Oil pressure presents the greatest strength of association with failure modes, indicating that it is a very informative variable for predicting failures. A significant variation in oil pressure can be an indication of mechanical failures or failures in the lubrication system, making this variable essential for predictive maintenance. -

coolant_temp (0.426) and engine_temp (0.417):

Coolant and engine temperatures have a strong association with failure modes. This suggests that monitoring these variables can be essential to predict failures related to overheating, cooling system failures or problems related to engine performance. Both are crucial for identifying malfunctions due to temperature rise and can be monitored to prevent severe damage.

1.8.1.1 Variables with intermediate Eta² (moderate association):

-

vibration_level (0.0725):

With an intermediate Eta², the vibration level shows a reasonable association with failure modes, especially for mechanical failures and wear. Although not as strong as oil_pressure or coolant_temp, vibration is an excellent indicator of problems in mechanical components, such as bearing wear or failures in moving parts. -

running_period (0.1061):

The operating period, or equipment operating time, shows a moderate relationship with the failure variable. Failures related to time of use may indicate accumulated wear or failures due to continuous use, which is particularly relevant for failures caused by long periods of operation.

1.8.1.2 Variables with lower Eta² (weak association strength):

-

fuel_consumption_per_hour (0.068):

The variable fuel_consumption_per_hour has a very weak association with failure modes, suggesting that, by itself, it is not a good predictor for failures. However, in more complex models, it can provide additional information about overall system performance, especially when combined with other more predictive variables. -

exhaust_temp (0.007):

Exhaust gas temperature presents the lowest strength of association among all the variables analyzed, suggesting that, in isolation, it is not a good variable predicting failures. This may indicate that exhaust temperature is not a sensitive enough measurement to detect early failure unless it is part of a more complex monitoring system.

1.8.2 Analysis of Significance Tests

-

Chi-Square: The p-value for the most relevant variables such as

oil_pressure, coolant_temp, engine_temp, etc., is very low (close to zero), indicating that there is a statistically significant difference between the failure modes in relation to these variables. This means that these variables can actually differentiate failure modes and are therefore useful for prediction. -

ANOVA (F-stat): The low p-value also suggests that the differences in means between the different failure modes for variables such as

oil_pressureandengine_tempare significant.

1.8.3 Impact of Failure Modes on Variables

- Calculating averages per failure mode for each numerical variable shows how different failure modes influence the variables. For example:

oil_pressurehas a significantly higher average for theOverheatingfailure mode compared to other failure modes, indicating that variations in this variable can be an important indicator of overheating-related failures.fuel_consumptionandengine_temppresent clear variations in the averages for the different failure modes, which reinforces their relevance for predicting failures.

Variables with a strong association with failure modes, such as oil_pressure, coolant_temp, engine_temp and engine_load, can be used reliably to make failure predictions. These variables showed good ability to differentiate failure modes and have a strong association with the categorical variable, making them suitable for a prediction model. Variables with weak association, on the other hand, should be discarded or treated with caution when building the model. In summary, the failure prediction model can be robust if it is built with variables that show a strong relationship with failure modes, such as temperatures and oil pressure.

2. Machine Learning Model Training and Evaluation

In this section, we focus on developing and evaluating a machine learning model to predict potential failures based on the collected data. The goal is to leverage the identified correlations and patterns to build a reliable predictive model that can assist in early fault detection and maintenance planning.

We will begin by preparing the dataset, including feature selection and preprocessing steps. Next, we will train different machine learning models and assess their performance using appropriate evaluation metrics. Finally, we will analyze the results to determine the most effective model for failure prediction and discuss potential improvements.

2.1 Dataset Preprocessing

Before training the machine learning model, it is essential to prepare the dataset to ensure that it is clean, structured, and suitable for analysis. This preprocessing step involves selecting relevant features, handling missing values, and splitting the dataset into training and testing sets.

# Adjusting the dataset for model training: data_1 = data[['timestamp', 'engine_id', 'engine_temp', 'oil_pressure','fuel_consumption', 'vibration_level', 'rpm', 'engine_load','coolant_temp', 'exhaust_temp', 'running_period','fuel_consumption_per_hour', 'engine_type', 'fuel_type', 'manufacturer','failure_mode', 'severity']]

First, a subset of the original dataset will be created, retaining only the most relevant variables for model training. The target variable was set to failed_mode, while certain features such as timestamp, manufacturer, engine_type, and fuel type were removed to prevent data leakage and reduce redundancy.

# Assuming 'failure_mode' is the target variable X = data_1.drop(['failure_mode','severity', 'timestamp', 'manufacturer', 'engine_type', 'fuel_type','engine_id', 'coolant_temp', 'fuel_consumption_per_hour', 'exhaust_temp' ] , axis=1) # Input variables # Separating the targets y= data_1['failure_mode']

Next, the dataset was divided into training and testing sets using a 70/30 split, ensuring that the class distribution was maintained through stratified sampling. To better understand the class balance, pie charts were generated to visualize the distribution of failure modes in the original dataset and the training set.

# Splitting the data for the failure_mode model X_train, X_test, y_train, y_test = train_test_split(X, y, test_size=0.3, random_state=42, stratify=y)

# Function to plot pie charts def plot_pie_chart(data, title, ax): data.value_counts().plot(kind='pie', autopct='%1.1f%%', startangle=90, ax=ax) ax.set_ylabel('') ax.set_title(title) # Creating side-by-side subgraphs fig, axs = plt.subplots(1, 2, figsize=(12, 6)) # Plotting the distribution of 'failure_mode' classes plot_pie_chart(y, 'Original Distribution - Failure Mode', axs[0]) plot_pie_chart(y_train, 'Training Distribution - Failure Mode', axs[1]) # Adjusting the layout plt.tight_layout() plt.show()

2.2 Model Training

With the dataset preprocessed, the next step is to train a machine learning model to predict engine failure modes. The training process involves selecting an appropriate model, defining hyperparameters, and fitting the model to the training data.

The goal is to develop a predictive model that can accurately classify different failure modes based on key engine parameters such as engine temperature, oil pressure, fuel consumption, vibration levels, and RPM. Various machine learning algorithms may be tested to determine the most effective approach, considering metrics such as accuracy, precision, recall, and F1-score.

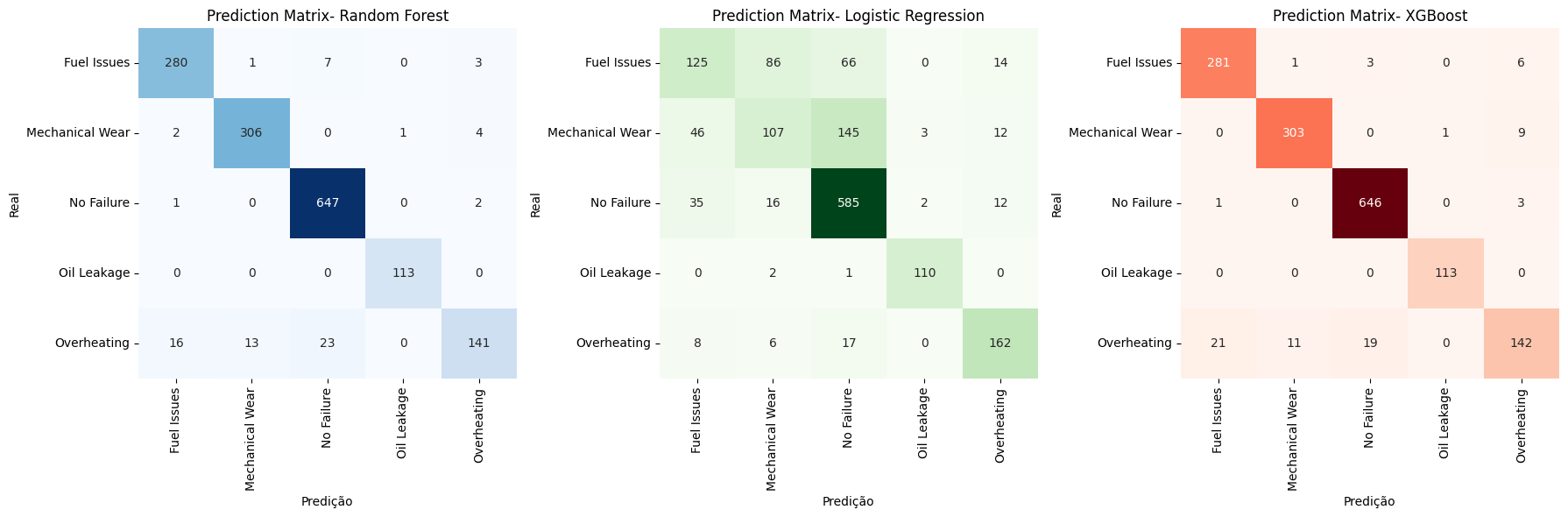

To evaluate the performance of different machine learning models in predicting engine failure modes, confusion matrices will be used. A confusion matrix provides a detailed breakdown of a model's predictions, showing the number of correctly and incorrectly classified instances for each failure mode.

The function below automates the process of training multiple models, generating predictions, and visualizing their confusion matrices. This allows for a quick comparison of model performance across different failure categories.

By analyzing the confusion matrices, we can identify patterns in misclassifications and assess which models best distinguish between failure modes. This analysis will help refine the model selection process and guide improvements in prediction accuracy.

# Function to plot confusion matrices for analyzing results def plot_confusion_matrices(models, X_train, y_train, X_test, y_test, class_names): fig, axes = plt.subplots(1, len(models), figsize=(18, 6)) colors = ['Blues', 'Greens', 'Reds'] for i, (name, model) in enumerate(models.items()): # Creating the pipeline for the current model pipeline = Pipeline(steps=[('preprocessor', preprocessor), ('classifier', model)]) # Training the model pipeline.fit(X_train, y_train) # Making predictions y_pred = pipeline.predict(X_test) # Calculating the confusion matrix cm = confusion_matrix(y_test, y_pred) # Plotting the confusion matrix sns.heatmap(cm, annot=True, fmt='d', cmap=colors[i], xticklabels=class_names, yticklabels=class_names, ax=axes[i], cbar=False) axes[i].set_title(f'Prediction Matrix- {name}') axes[i].set_xlabel('Predição') axes[i].set_ylabel('Real') plt.tight_layout() plt.show()

After selecting the machine learning models, the next step is to train, evaluate, and compare their performance in predicting engine failure modes.

The process begins by encoding the target variable (failure_mode) using Label Encoding to convert categorical failure types into numerical values. Then, a preprocessing pipeline is defined to handle missing values and normalize numerical features, ensuring that models receive properly scaled data.

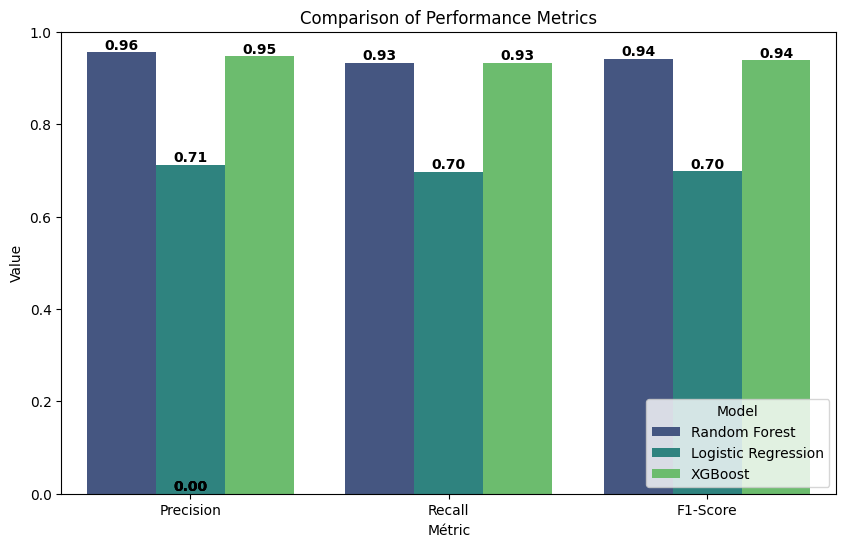

Three different models are trained and evaluated:

Random ForestLogistic RegressionXGBoost

Each model is trained using the preprocessed dataset, and its performance is assessed using classification reports, cross-validation scores, and confusion matrices. Additionally, a bar chart visualization is generated to compare key metrics (Precision, Recall, and F1-Score) across models.

This comprehensive evaluation will help determine the most effective model for predicting engine failures based on sensor data.

# Initialize LabelEncoder label_encoder = LabelEncoder() # Coding the classes y_train_encoded = label_encoder.fit_transform(y_train) y_test_encoded = label_encoder.transform(y_test) # Defining a basic preprocessing (imputation and normalization) preprocessor = ColumnTransformer(transformers=[('num', Pipeline([('imputer', SimpleImputer(strategy='mean')),('scaler', StandardScaler())]), X_train.columns)]) # Creating pipelines for each model models = { 'Random Forest': RandomForestClassifier(n_estimators=150, random_state=42), 'Logistic Regression': LogisticRegression(random_state=42), 'XGBoost': XGBClassifier(random_state=42) } # Dictionary to store metrics metrics_data = [] # Class name: class_names = ['Fuel Issues', 'Mechanical Wear', 'No Failure', 'Oil Leakage', 'Overheating'] # Training and evaluating each model for name, model in models.items(): pipeline = Pipeline(steps=[('preprocessor', preprocessor), ('classifier', model)]) # Training the model with the coded classes pipeline.fit(X_train, y_train_encoded) # Making predictions with the coded classes y_pred_encoded = pipeline.predict(X_test) # Get the rating report report = classification_report(y_test_encoded, y_pred_encoded, output_dict=True) # Evaluating the model print(f"\n{name} - Classification Report:") print(classification_report(y_test_encoded, y_pred_encoded)) # Calculating cross-validation score cv_scores = cross_val_score(pipeline, X_train, y_train_encoded, cv=5) print(f"{name} - Cross Validation Score: {cv_scores.mean():.4f} (+/- {cv_scores.std():.4f})\n") # Store metrics (avg macro) metrics_data.append({'Model': name, 'Precision': report['macro avg']['precision'], 'Recall': report['macro avg']['recall'], 'F1-Score': report['macro avg']['f1-score']}) # Plotting the confusion matrices plot_confusion_matrices(models, X_train, y_train_encoded, X_test, y_test_encoded, class_names) # Create DataFrame for visualization df_metrics = pd.DataFrame(metrics_data).melt(id_vars=['Model'], var_name='Metric', value_name='Value') # Create bar chart figure plt.figure(figsize=(10, 6)) ax = sns.barplot(x='Metric', y='Value', hue='Model', data=df_metrics, palette='viridis') # Add values to the top of the bars for p in ax.patches: ax.annotate(f'{p.get_height():.2f}', (p.get_x() + p.get_width() / 2., p.get_height()), ha='center', va='bottom', fontsize=10, fontweight='bold', color='black') # Chart settings plt.ylim(0, 1) plt.title('Comparison of Performance Metrics') plt.ylabel('Value') plt.xlabel('Métric') plt.legend(title='Model') plt.show()

Random Forest - Classification Report:

| Class | Precision | Recall | F1-score | Support |

|---|---|---|---|---|

| 0 | 0.94 | 0.96 | 0.95 | 291 |

| 1 | 0.96 | 0.98 | 0.97 | 313 |

| 2 | 0.96 | 1.00 | 0.98 | 650 |

| 3 | 0.99 | 1.00 | 1.00 | 113 |

| 4 | 0.94 | 0.73 | 0.82 | 193 |

| Accuracy | 0.95 | 1560 | ||

|---|---|---|---|---|

| Macro Avg | 0.96 | 0.93 | 0.94 | 1560 |

| Weighted Avg | 0.95 | 0.95 | 0.95 | 1560 |

Random Forest - Cross Validation Score: 0.9451 (+/- 0.0047)

Logistic Regression - Classification Report:

| Class | Precision | Recall | F1-score | Support |

|---|---|---|---|---|

| 0 | 0.58 | 0.43 | 0.50 | 291 |

| 1 | 0.49 | 0.34 | 0.40 | 313 |

| 2 | 0.72 | 0.90 | 0.80 | 650 |

| 3 | 0.96 | 0.97 | 0.96 | 113 |

| 4 | 0.81 | 0.84 | 0.82 | 193 |

| Accuracy | 0.70 | 1560 | ||

|---|---|---|---|---|